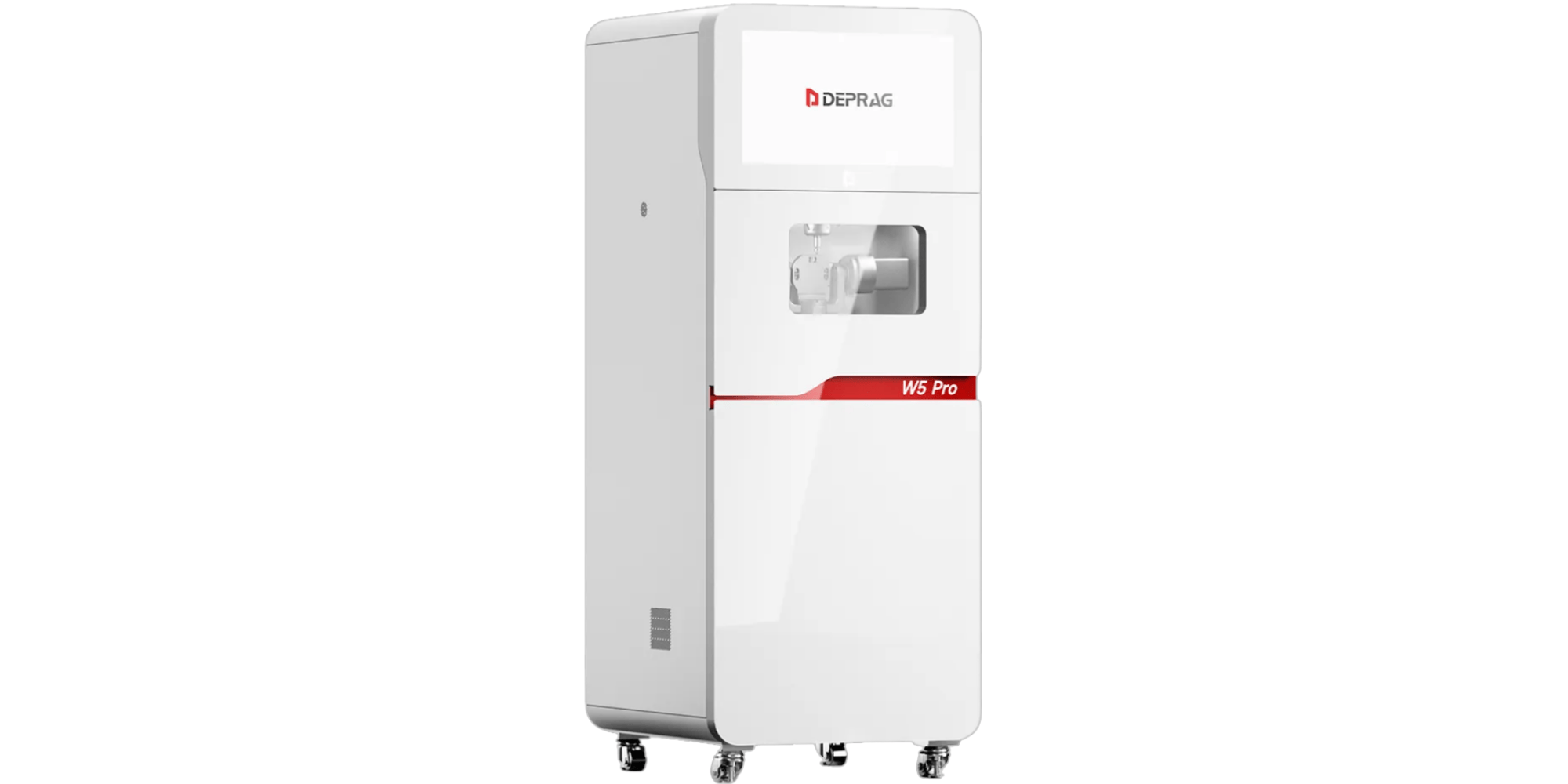

DEPRAG - W5 PRO Dry- Wet Dental Milling unit Set -Water Cooling System - Tank - Cabinet - Self Calibration - Remote assistance - # DEP-0003

14154_f.jpg)

14153_f.jpg)

Description

W5 PRO

The floor-standing type 5-axis Milling machine for dry and WET machining

✅ Self-Calibration

✅ Large spindle and high rigidity

Download the brochure for all details. Download ↓

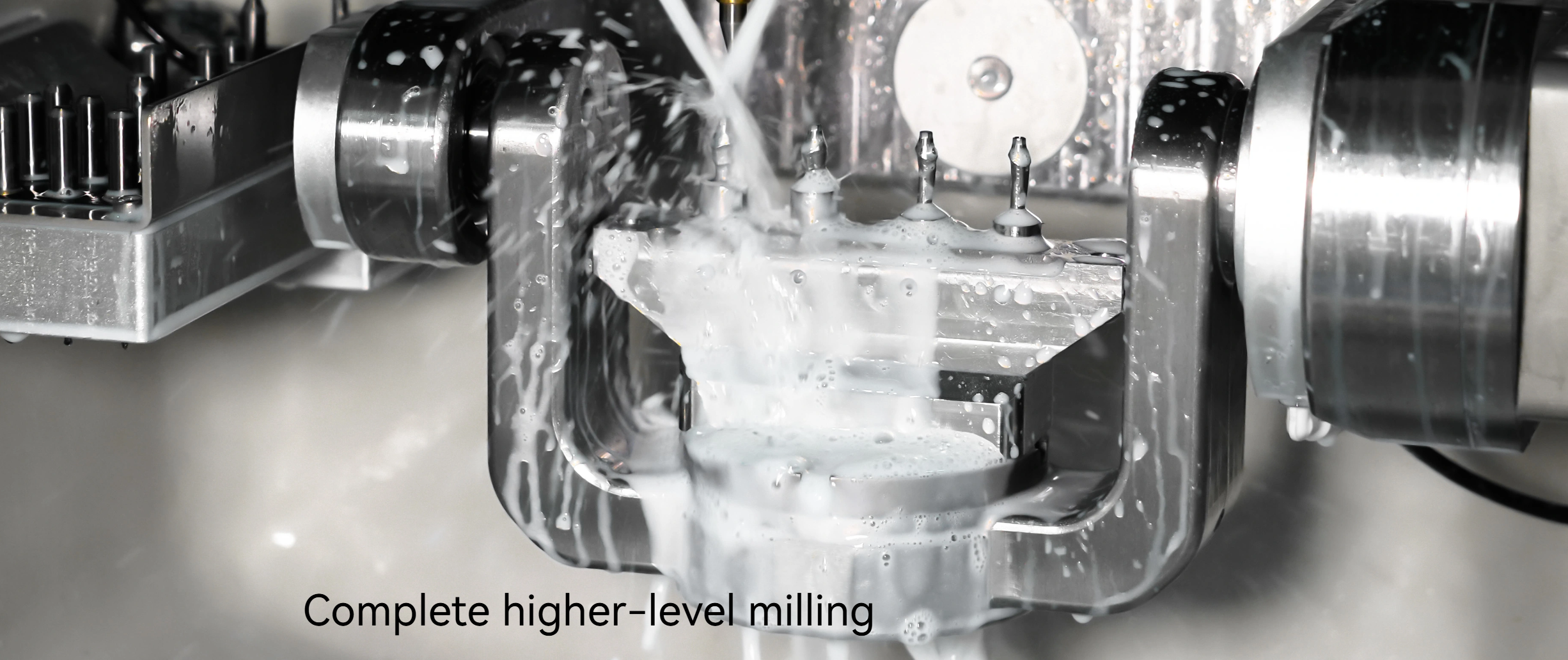

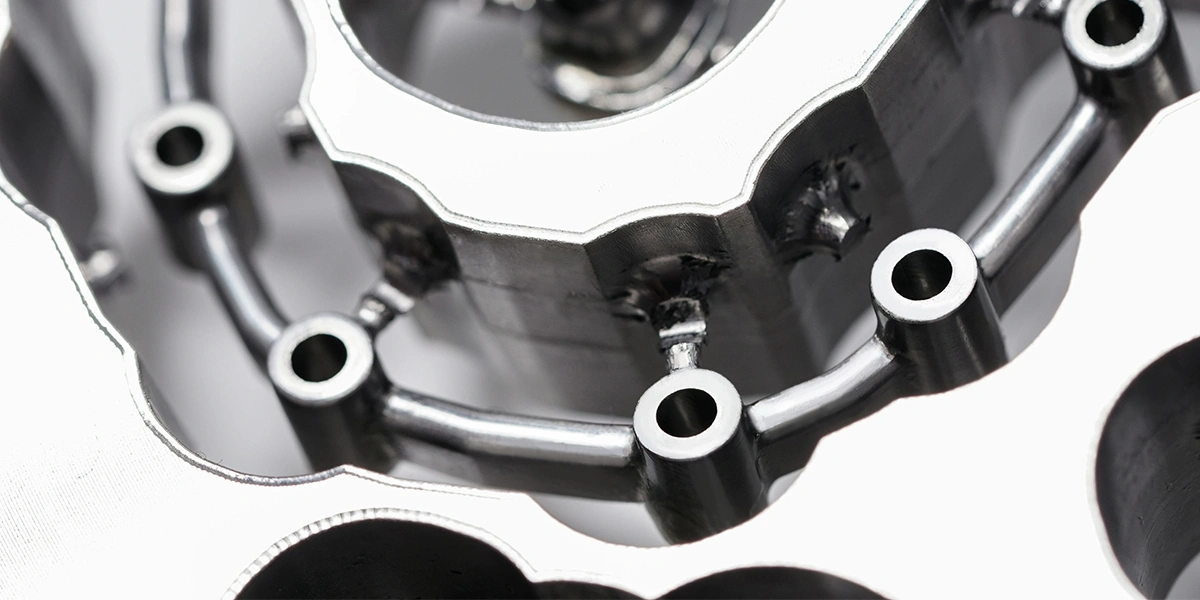

The best choice for Milling CoCr

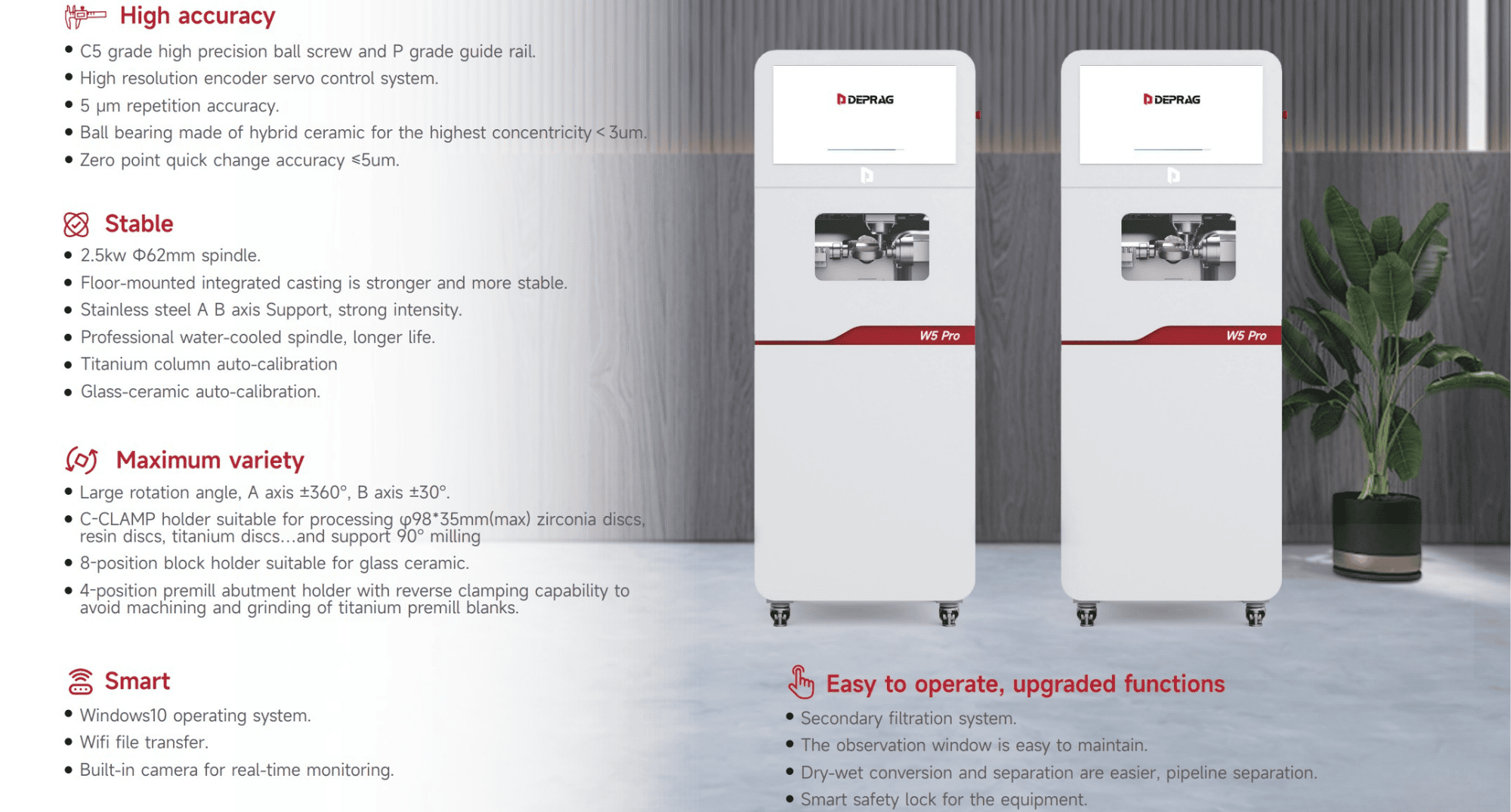

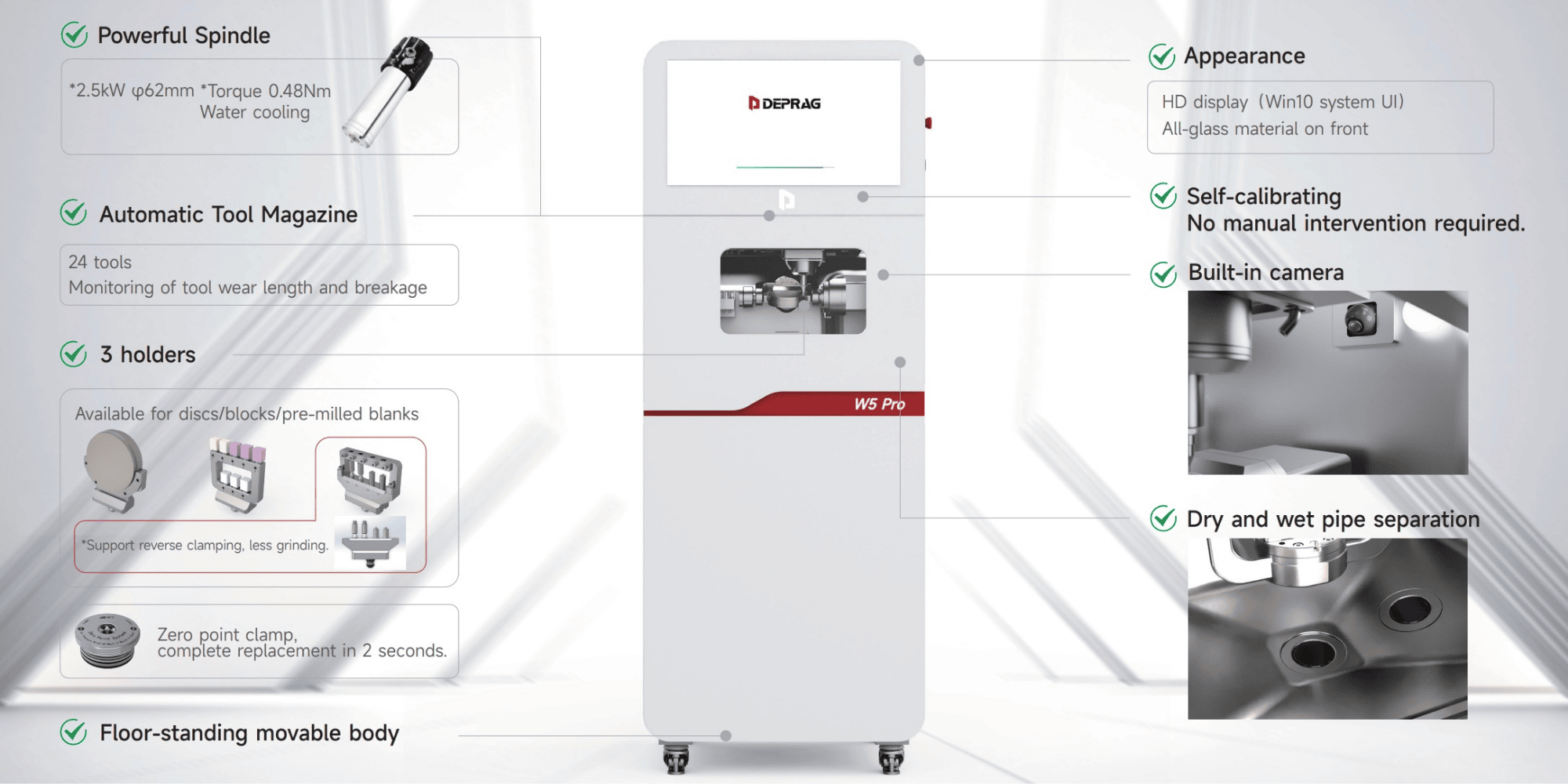

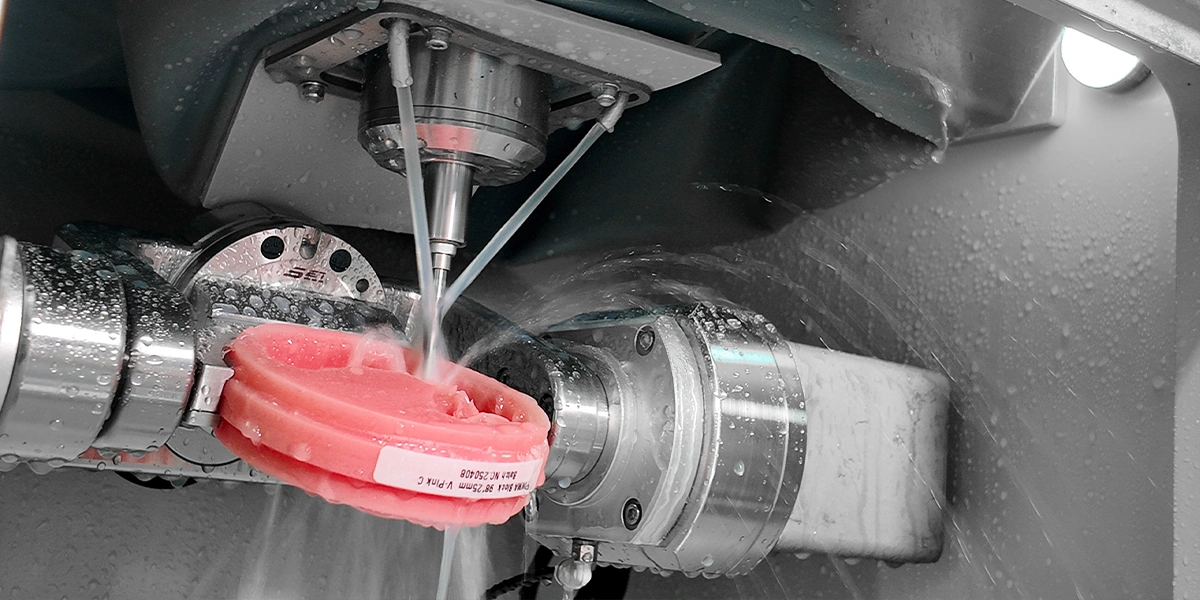

The 2.5kW large spindle equipped in the W5 Pro provides powerful power for CoCr Milling. Meanwhile, the spindle torque of 398Ncm enables the equipment to easily complete the Milling work of metal materials.

Achieving a 30% Efficiency Enhancement

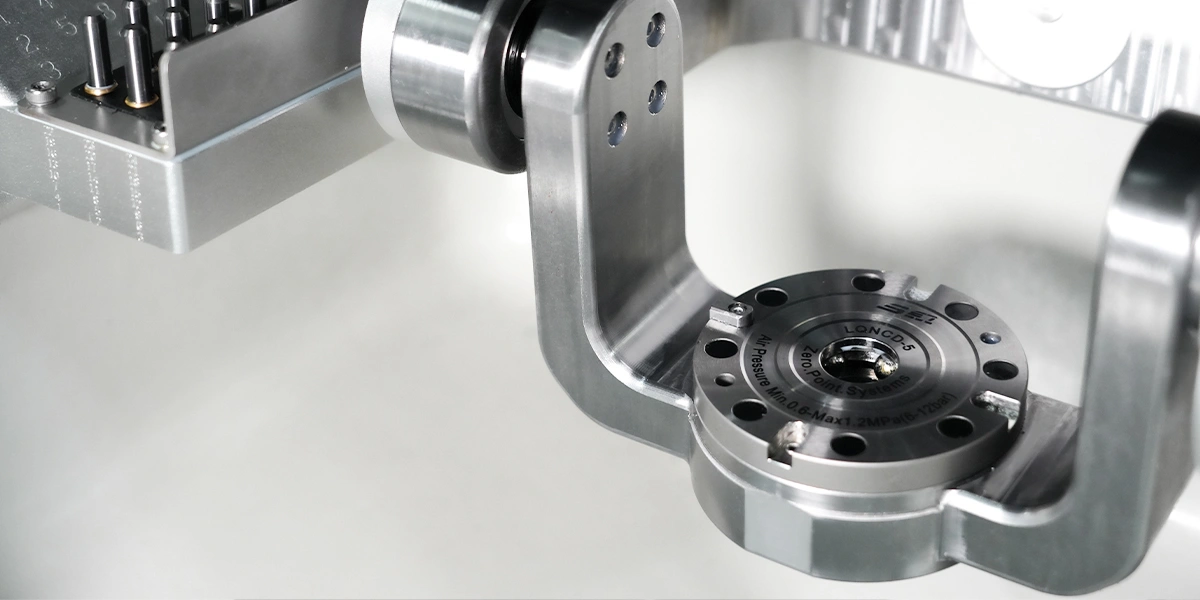

The zero-point quick change function has been upgraded. Changing the fixture only takes 1 to 2 seconds, which is fast and stable.

The addition of the auto-Calibration has shortened the Calibration time from 40 minutes to less than ten minutes.

High Milling accuracy

The W5 Pro is capable of performing precise thread Milling and incorporates an automatic Calibration function, reducing the error to less than 0.003mm.The success rate of getting teeth is over 97%.

Stable working performance

Durable and robust construction – Cast iron frame, nickel-plated anti-corrosion coating and cast iron Milling chamber. The added Auto-Drainage Air Filter can reduce maintenance issues caused by neglected drainage.

FEATURES

WIDE RANGE OF APPLICATION

• 2.5kw Φ62mm spindle, 398Ncm High-Torque Milling;

• Inovance Servo Motors;

• 90° Vertical Milling;

AUTOMATED OPERATION

• Auto-Calibration;

• Smart Tool Management; Automatic tool change, tool magazine life monitoring.

• Remote Control, Support mobile phones and computers;

MULTI-FUNCTIONAL DESIGN

• Fully Automatic Cleaning, 360° Rotating Nozzles for WET/dry switching;

• Dual dry/WET tool magazine design, 24 positions * 2;

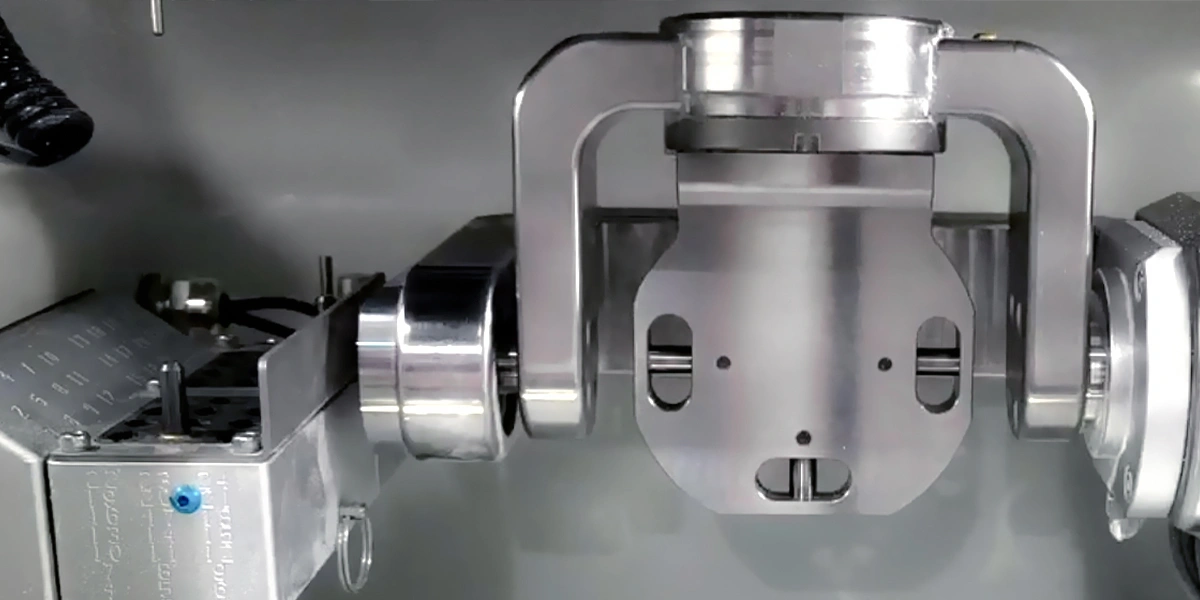

• 3 Holder Types: 8-position blocks, 4-position pre-milled blanks (supports reverse clamping to reduce grinding process);

USER-FRIENDLY FEATURES

• 23.8" Touchscreen (Windows 10)

• Built-in HD Camera, real-time monitoring and support recording.

• Zero-Point Quick Change

• Schneider Circuit Protection

CONVENIENT AND RELIABLE

• Auto-Drainage Air Filter

• Comprehensive Log System

• Floor-mounted integrated casting is stronger and more stable.

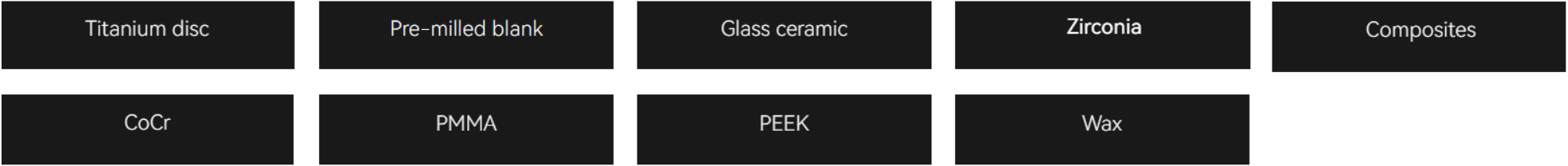

MACHINABLE MATERIALS

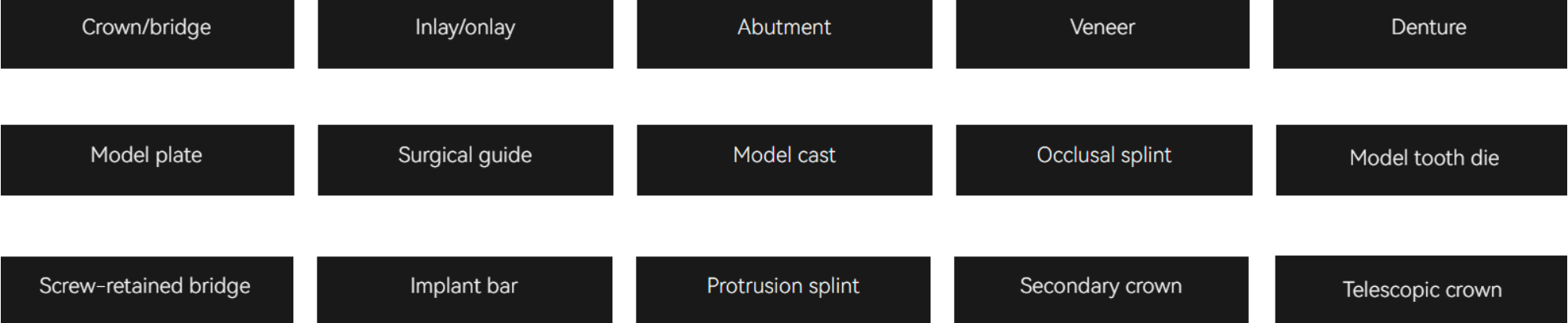

APPLICATIONS

ACCESSORIES

VIDEOS

EQUIPMENT PARAMETERS

GENERAL

Processing mode

Millable material

Applications

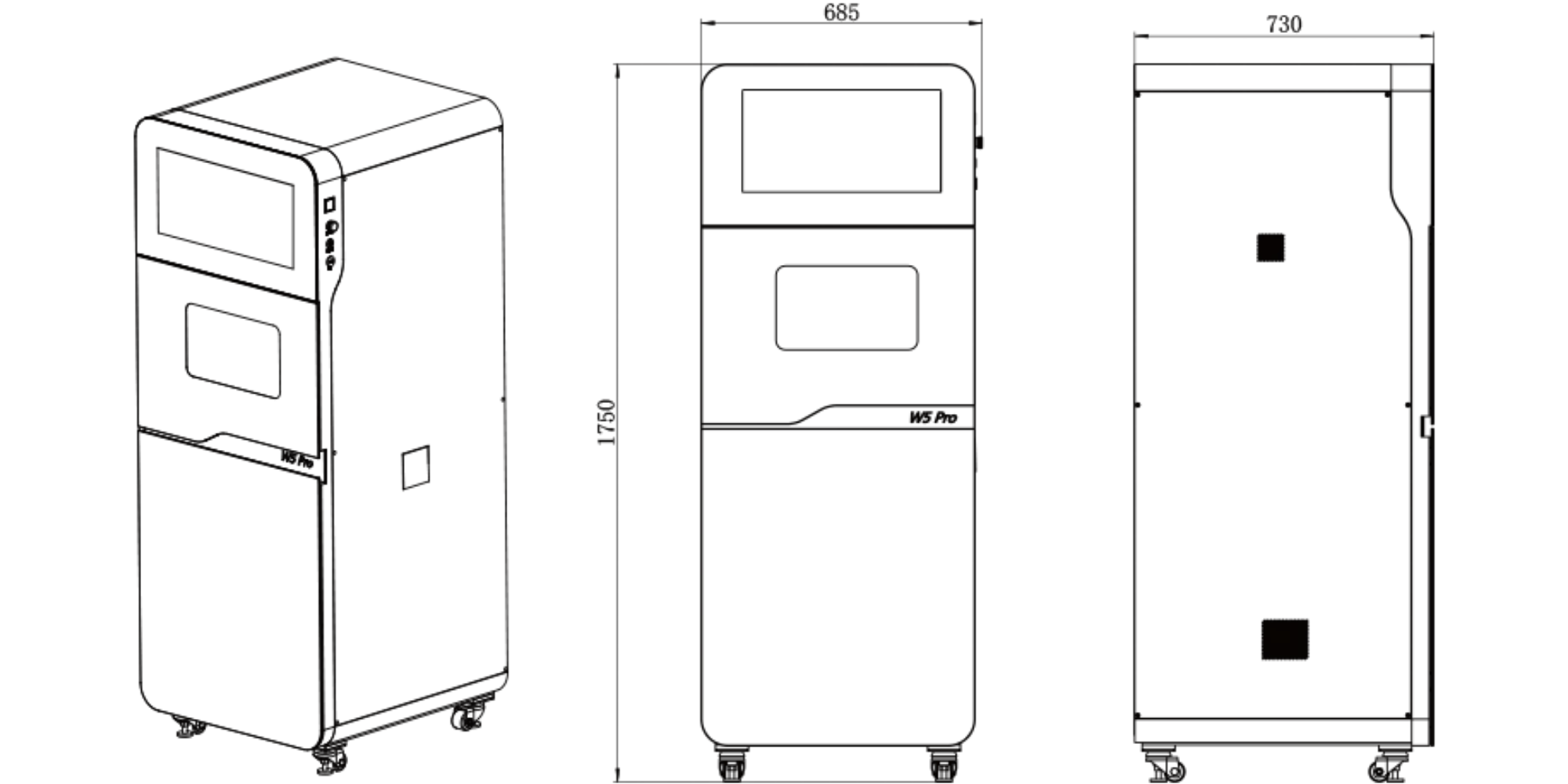

Dimension

Weight

Power

Air supply pressure

Air flow

Dry and WET

Zirconia, Glass ceramics, Plastics | Wax, Composite, Premill, Titanium, CoCr

Crown | Bridge, Veneer, Inlay | Onlay, Abutment, Denture, Screw-retained bridge, Model cast, Occlusal splint, Surgical guide, Implant bar

685× 730 ×1750mm

300 kg

220V/3.5kW

>0.5 MPa

>100 L/min

STRUCTURE PARAMETERS

Basic construction

Number of axes

X-axis working stroke

Y-axis working stroke

Z1-axis working stroke

Rotary axis A-axis

Rotary axis B-axis

Tools-positions

Tool setting accuracy

Maximum feed speed

Maximum idle speed

Aluminium

5

220mm

145mm

130mm

0~360°

-30°~+30°

24

0.01mm

4000mm/min

8000mm/min

SPINDLE

Speed

Power

Collet

Cooling method

10,000~60,000 rpm/min

2.5kW

Φ6 mm

Water Cooling

SCOPE OF DELIVERY

CAM Software

Clamps

Millbox / Hyperdent / WorkNC available

Half-open blank holder(C-CLAMP)

Block holder

Premill Abutment holder