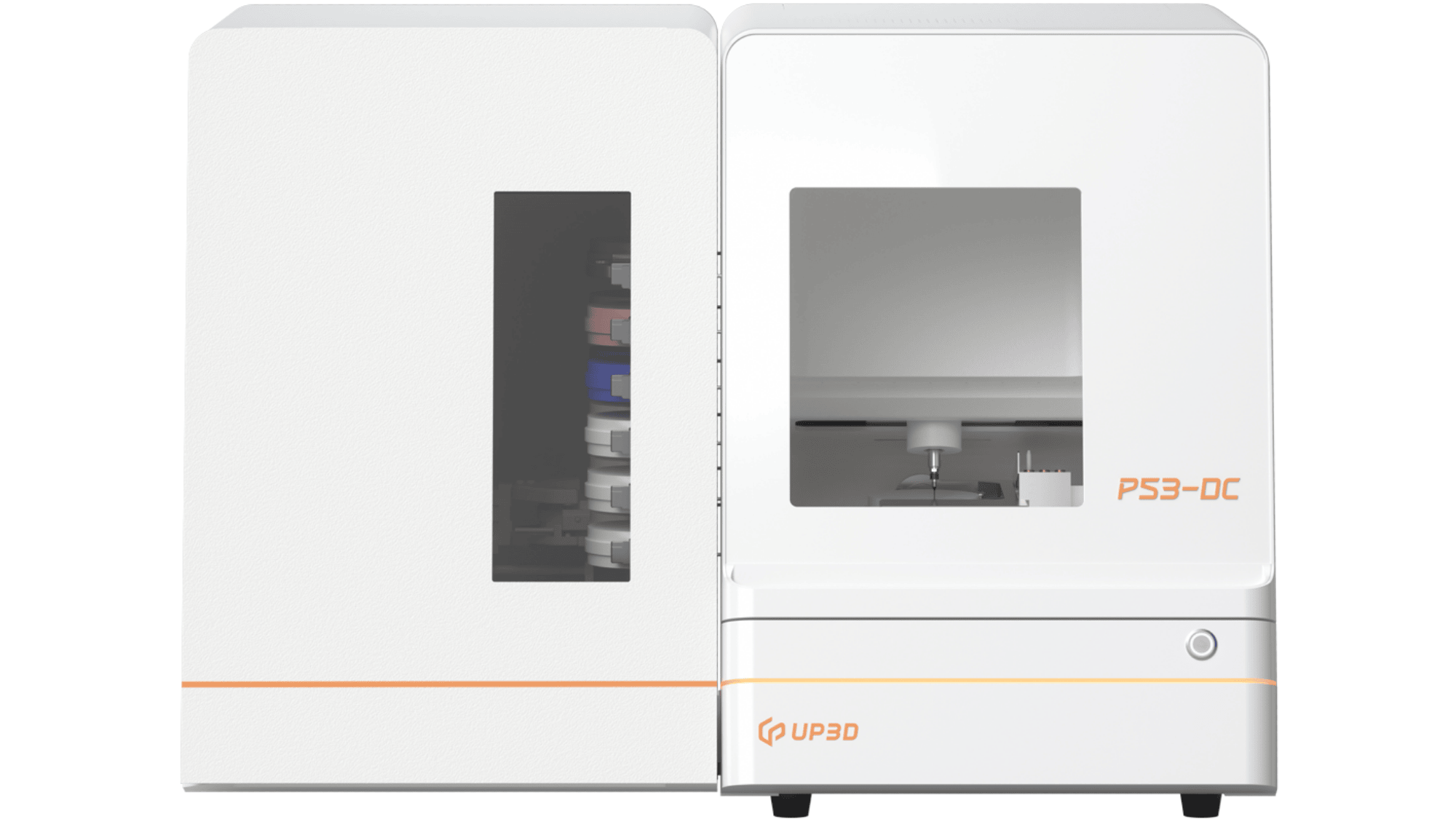

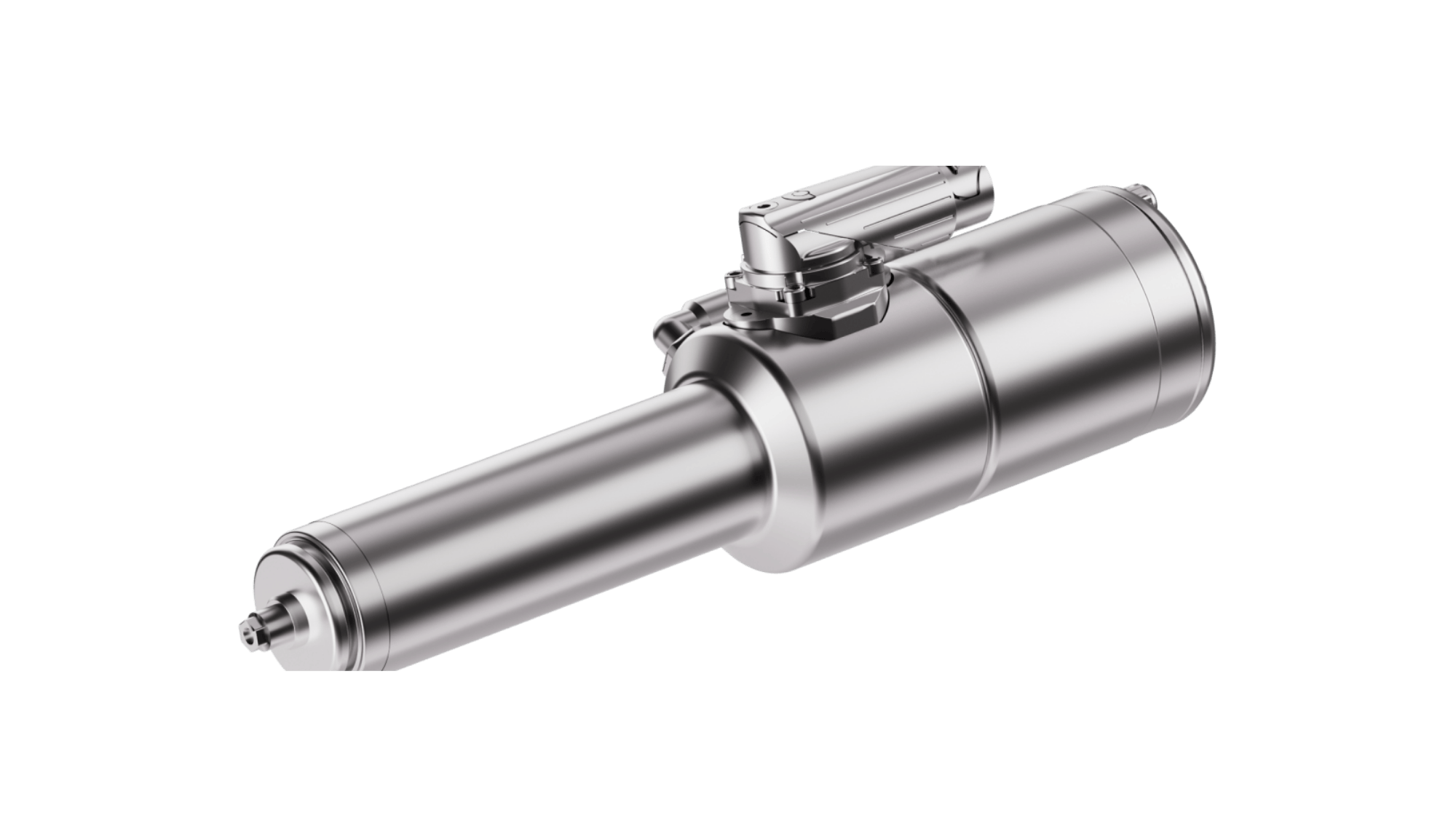

UP3D - P53DC Smart dental 5-axis milling unit with 12 Discs Changer 110v # P53DC

15590_f.jpg)

15589_f.jpg)

15588_f.jpg)

15587_f.jpg)

15586_f.jpg)

15585_f.jpg)

Description

DESCRIPTIONS

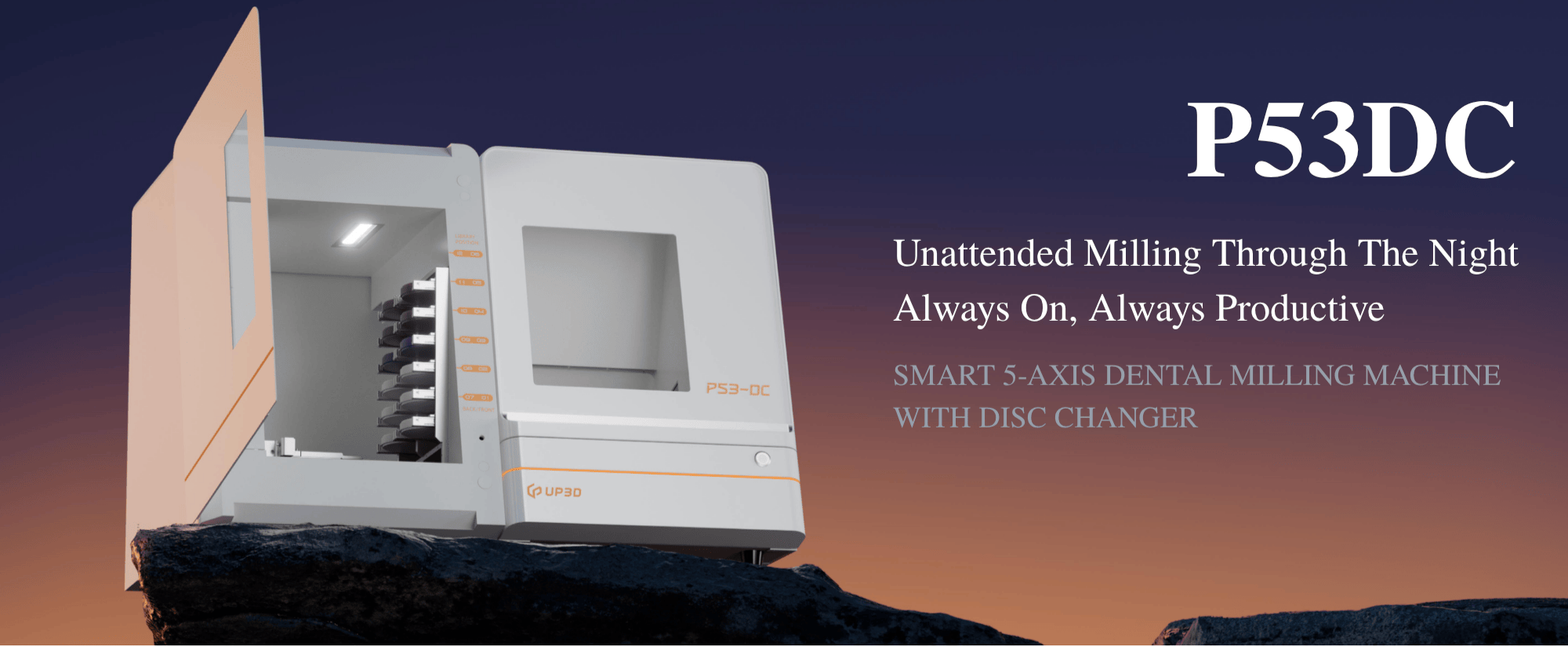

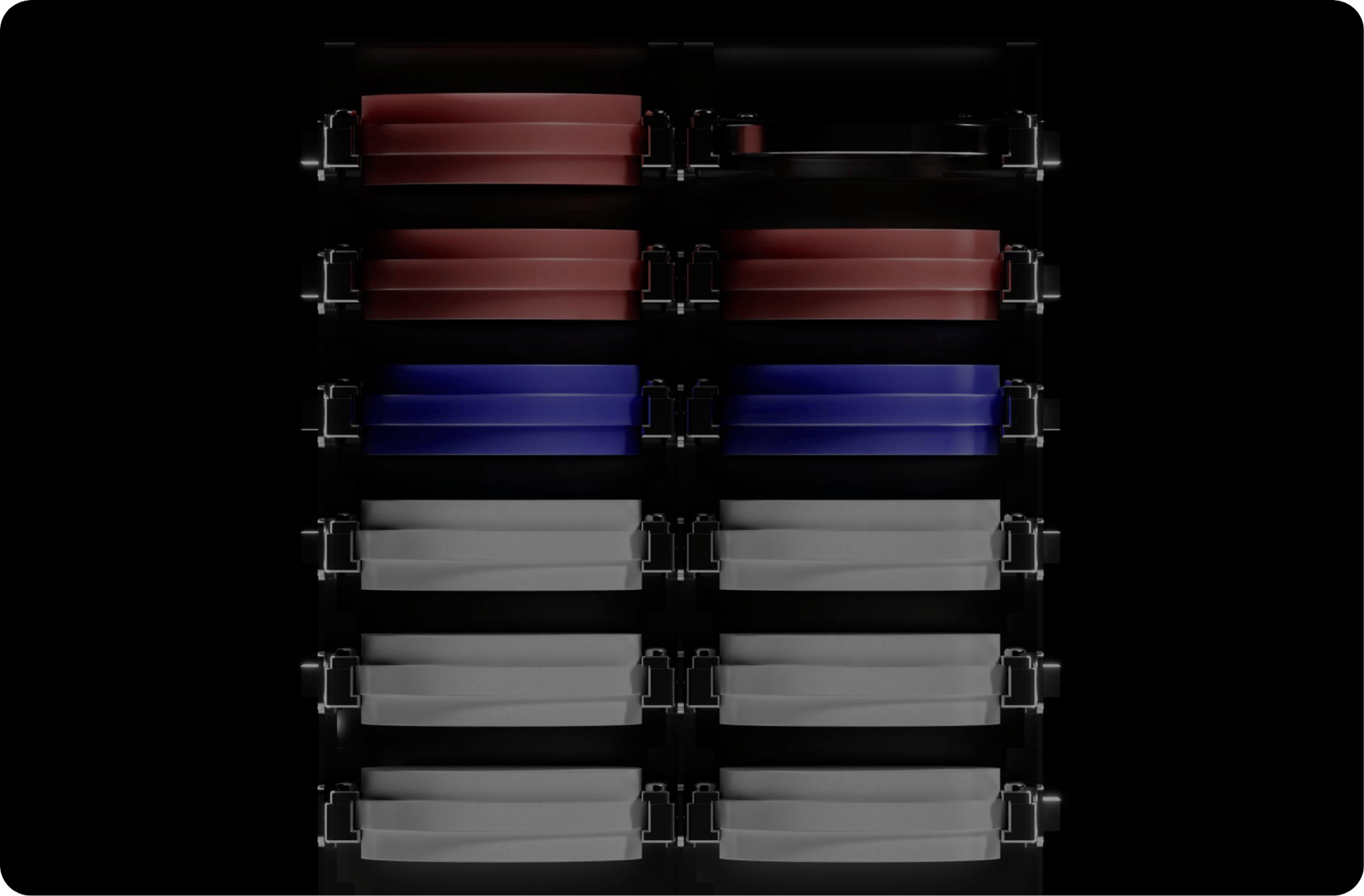

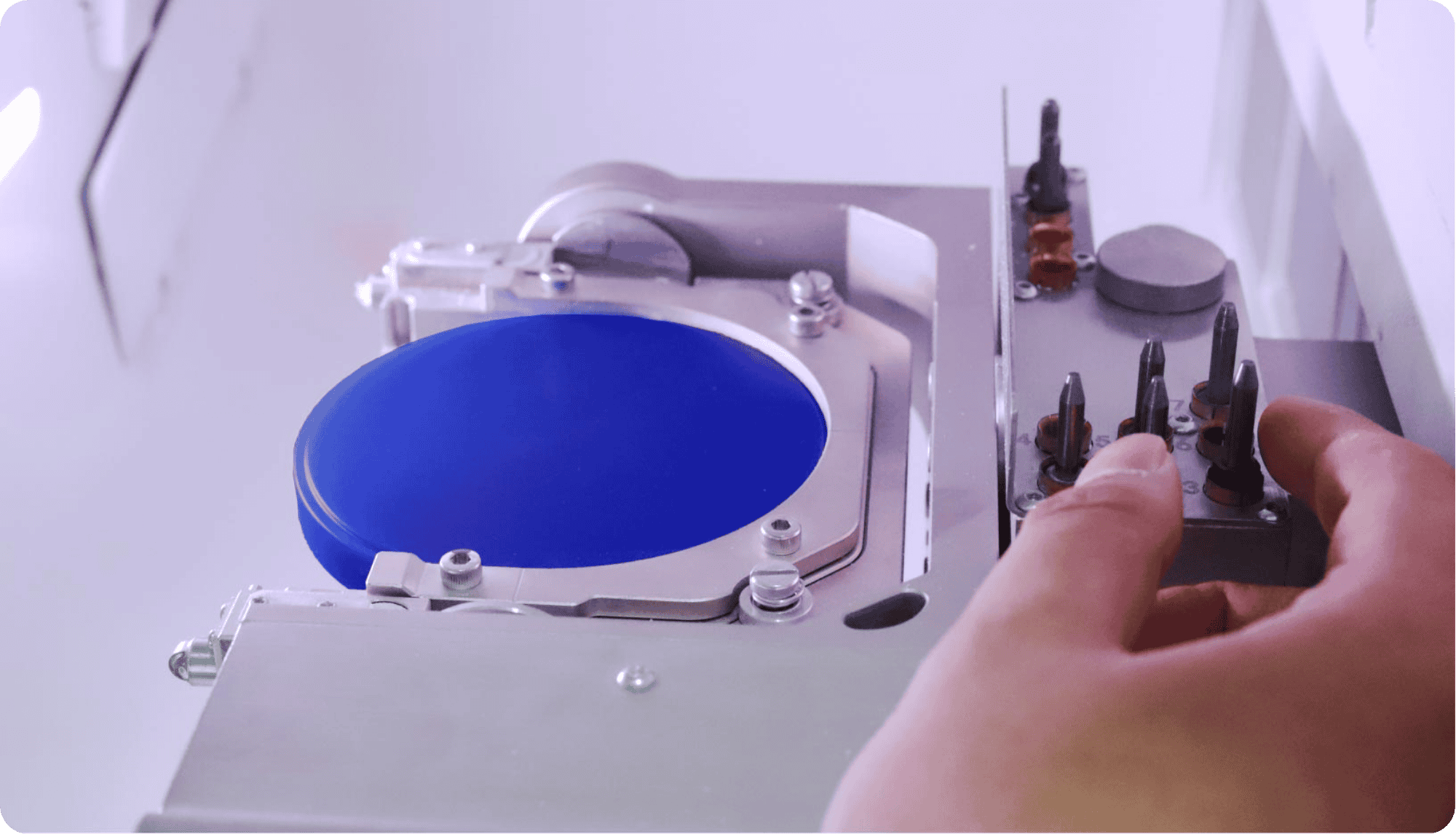

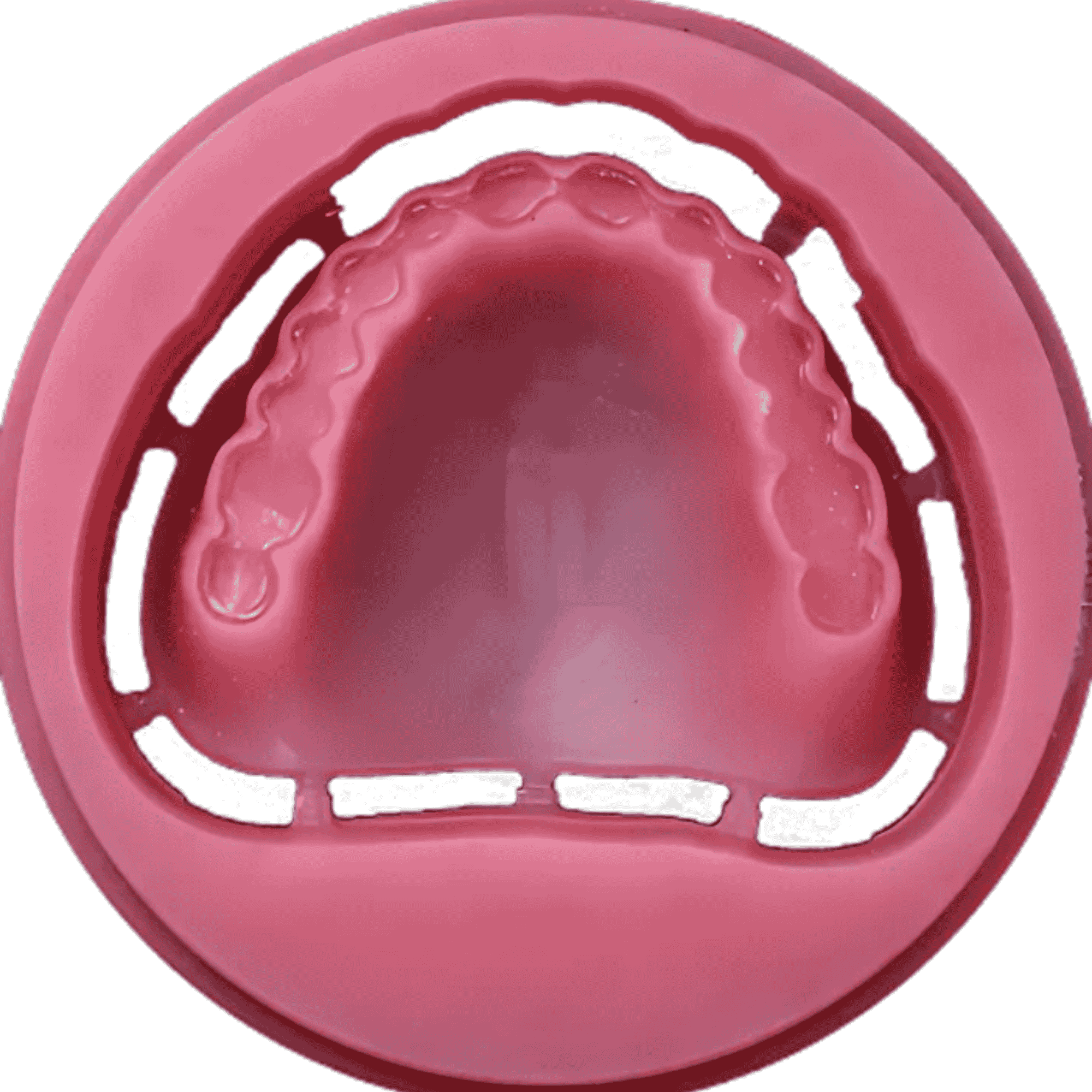

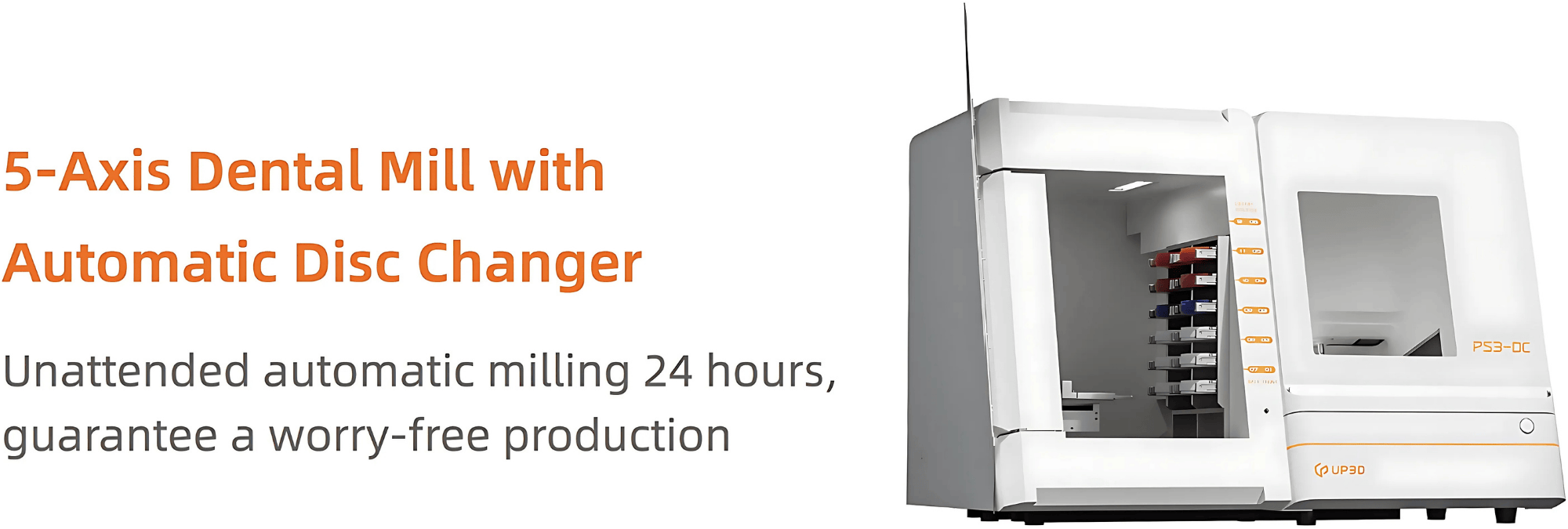

Non-Stop Production with Automatic Disc Changer

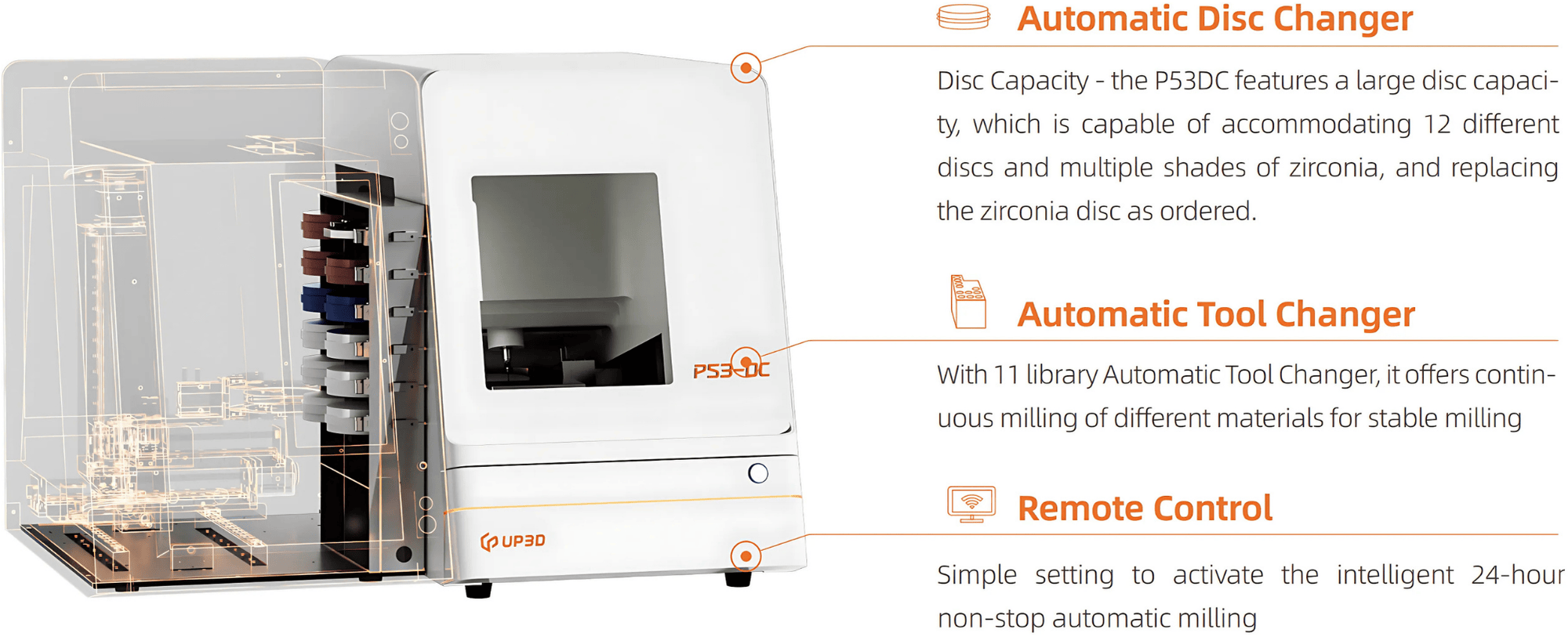

The P53DC is built for high-efficiency, continuous Milling. lts automatic disc changer accommodates up to 12 discs, supporting multiple materi-als like zirconia, PMMA, and CoCr for versatile dental applications.Featuring quick-switch compatibility for both 98mm discs and up to sixblocks of various sizes, the P53DC ensures seamless transitions without interrupting workflow.

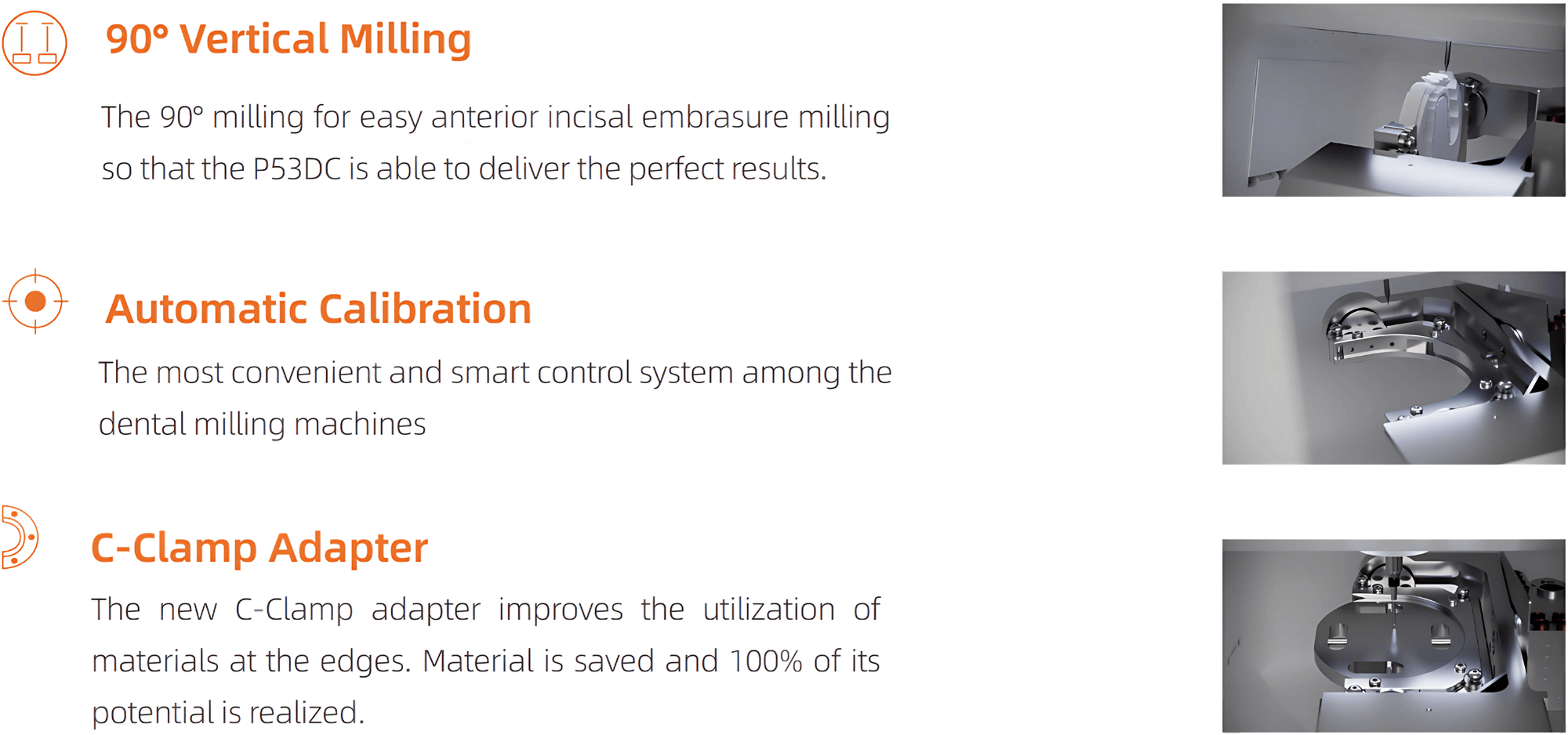

90° Milling for Bionic Aesthetics

Designed for areas requiring high precision and aesthetics, 90-degree vertical Milling precisely textures the labial (or buccal) surfaces, en-abling more diverse anterior tooth aesthetics. This approach significantly reduces complex post-processing time and lowers labor costs.

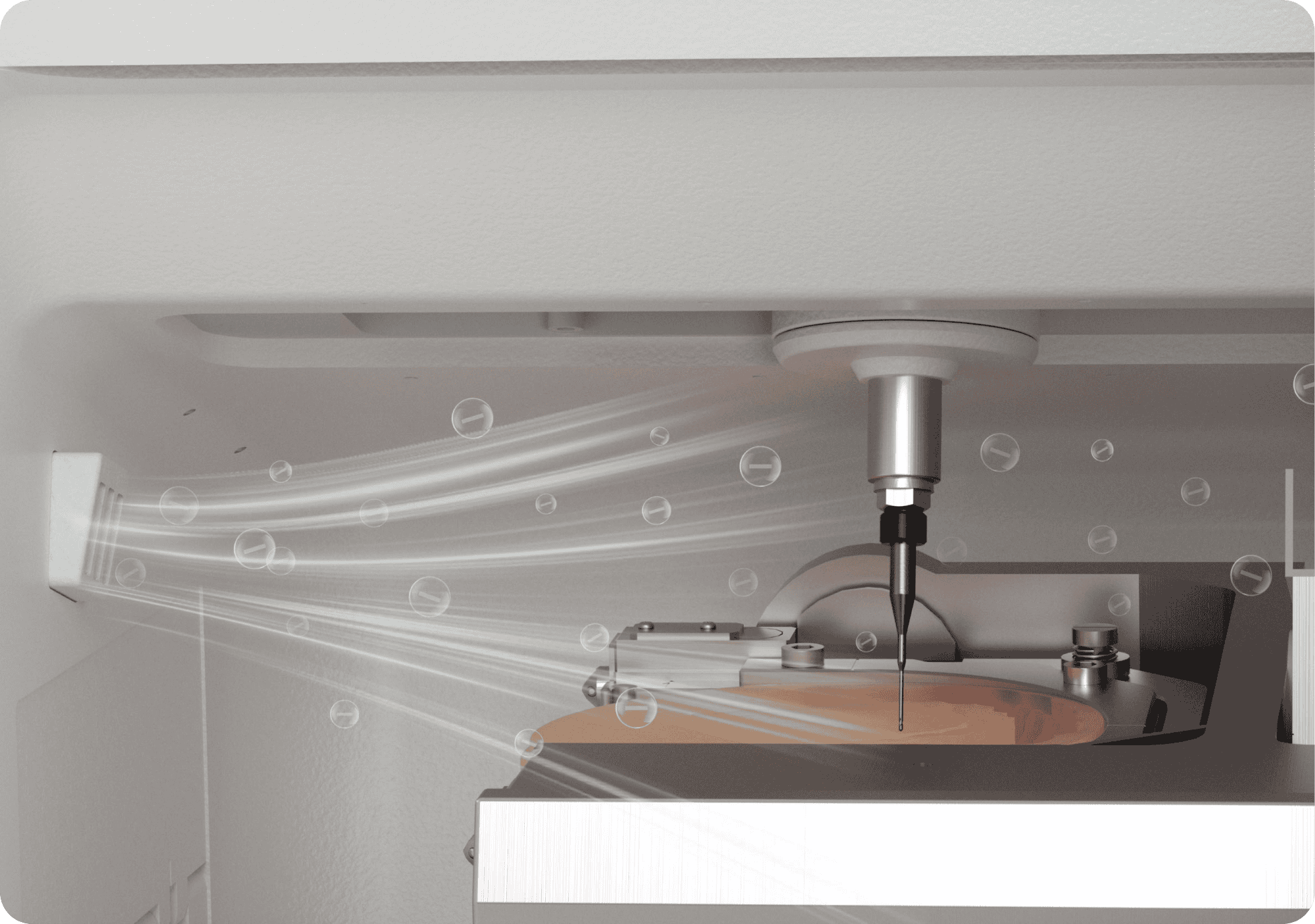

Enhanced lonizer: Cleaner Milling, Better Results

The ionizer effectively neutralizes static electricity, preventing debris from adhering to the working chamber and tools, which could compromise Milling accuracy. This ensures long-term, stable Milling of PMMA and resin materials, delivering a clean and smooth Milling process that enhances overall quality.

FEATURES

Smart Material Management

The Smart Material Management System streamlines production with one-click order import, automatically recognizing design type, color, and thickness for accurate sorting. Intelligent disc selection maximizes material usage, while optimized nesting minimizes waste and enhances efficiency for continuous Milling.

Innovative C-Clamp Design

The C-clamp design expands buccal Milling space, improves material nesting and edge utilization, and maximizes material savings, delivering greater economic benefits to dental labs.

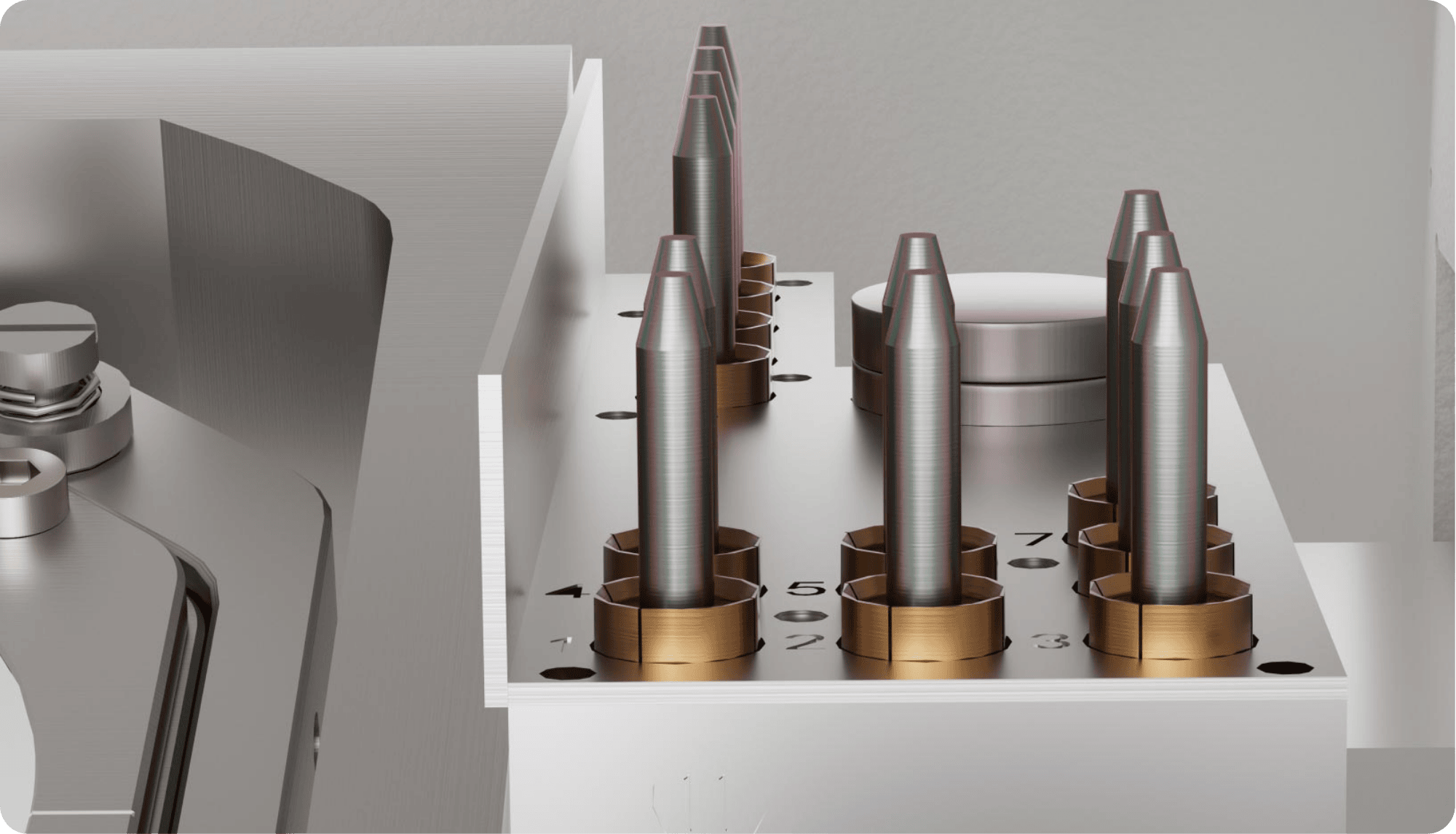

Automatic Tool Changer

With an 11-tool capacity, the automatic tool changer supports continuous Milling across different materials, minimizing downtime, boosting efficiency, and ensuring precision and stability while reducing maintenance costs.

Custom Strategy for Precision Milling

With a custom 0.2mm micro-carving tool and a 0.6mm extended Milling tool, it precisely mills occlusal details, perfectly replicating tooth morphology.

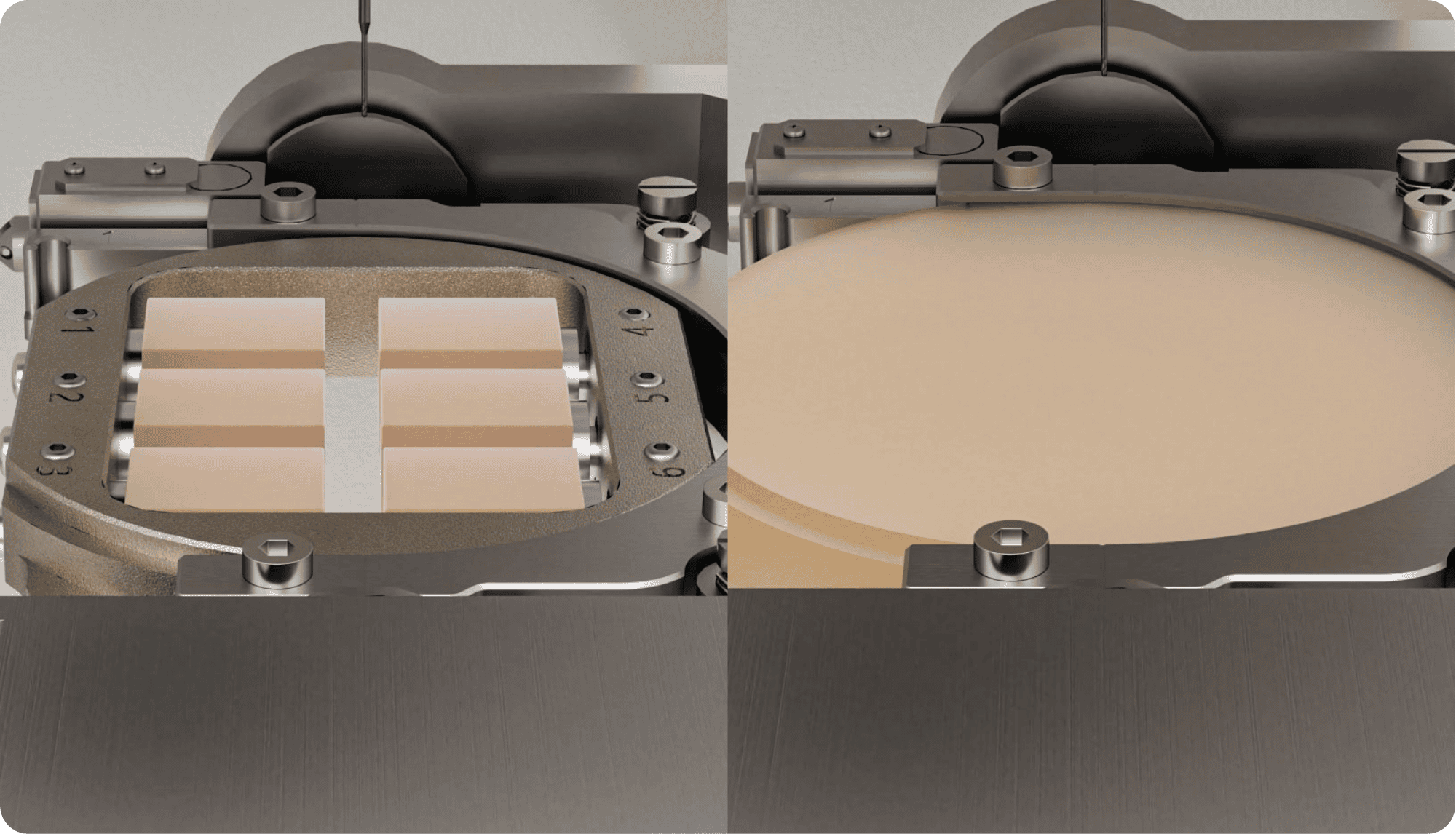

Compatible Various Material Forms

Whether it's composite resin disc or block, the P53DC handles it with ease, providing greater flexibility for your dental lab.

Enhanced Spindle

Spindle Temperature Monitoring: Built-in CNC overload warning system prevents overheating and spindle damage.Advanced Spindle Protection: Precise pressure regulator ensures stable spindle cooling and air pressure, greatly extending spindle life and ensuring smooth operation at peak performance.

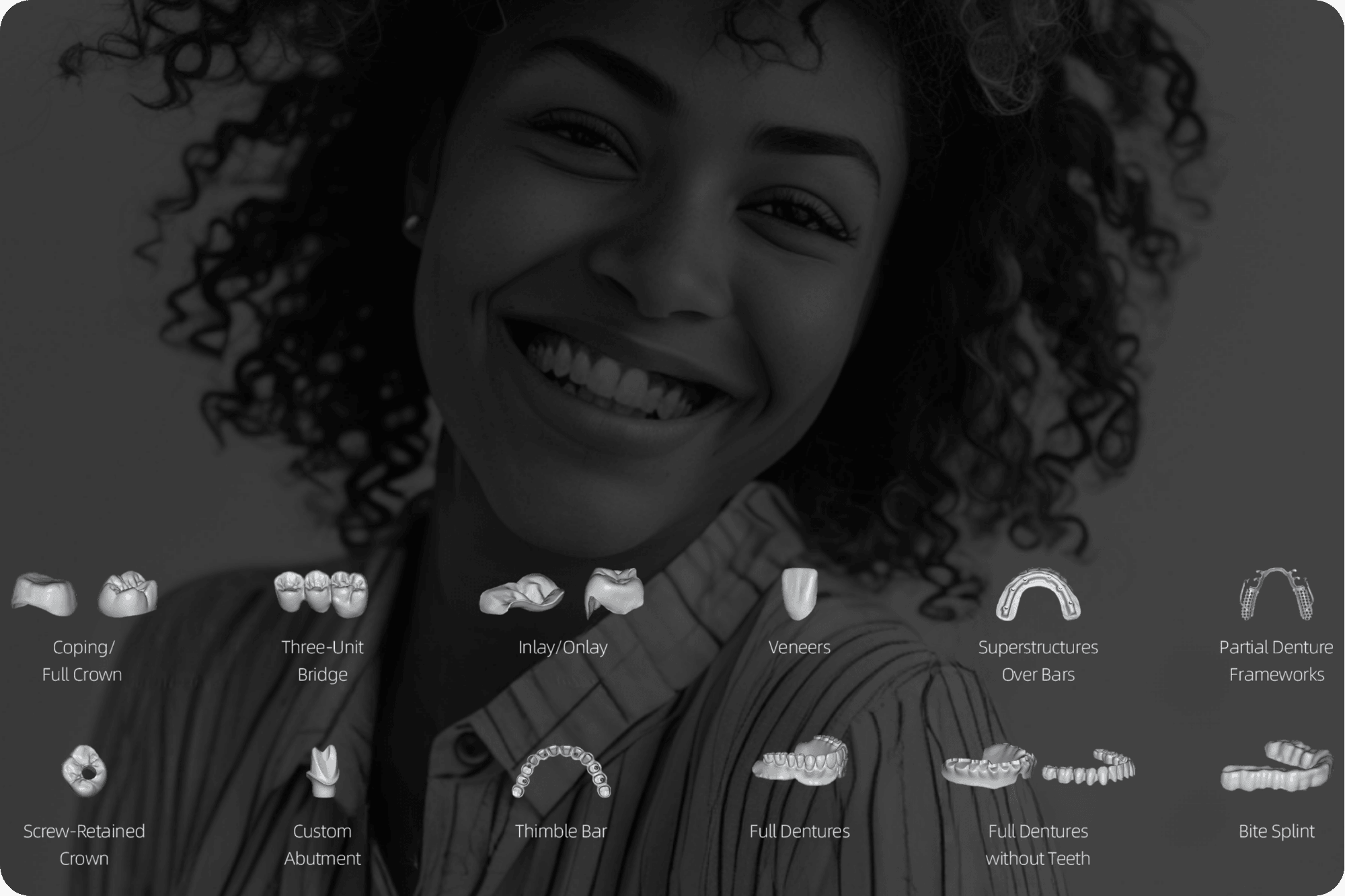

WIDE RANGE OF APPLICATIONS

Freedom of Choice in Creation

WHY NOT WORK LESS, MILL MORE AND LIVE MORE?

APPLICABLE MATERIALS

Model

Dimension

Weight

Input voltage

Maximum power

Spindle power

Axis quantity

Mil'ling range

Mil'ling mode

Max rotation speed

Max feed rate

Tools quantity

Disc library quantity

Tools changing method

Spindle cooling

Mil'ling materials

Mil'ling time

Tools diameter

Disc specification

Spindle clamping diameter

CAM supported

Data transmission

P53 DC

720×875×630mm

130kg

AC 200~240V 50~60Hz

1.1KW

0.35KW at max

5-axis simultaneous motion

X/Y/Z:167/206/104mm A:±30° B:±360°

Dry Mil'ling

60,000rpm

3000mm/min

11

12

Automatic (Air pressure >0.5MPa )

Air cooling with compression air , air flow>50L/min

Zirconia, Wax, PMMA, PEEK and soft materials

Coping : Zirconia-10min Wax- 4.5min Crown : Zirconia-13min Wax-5.5min

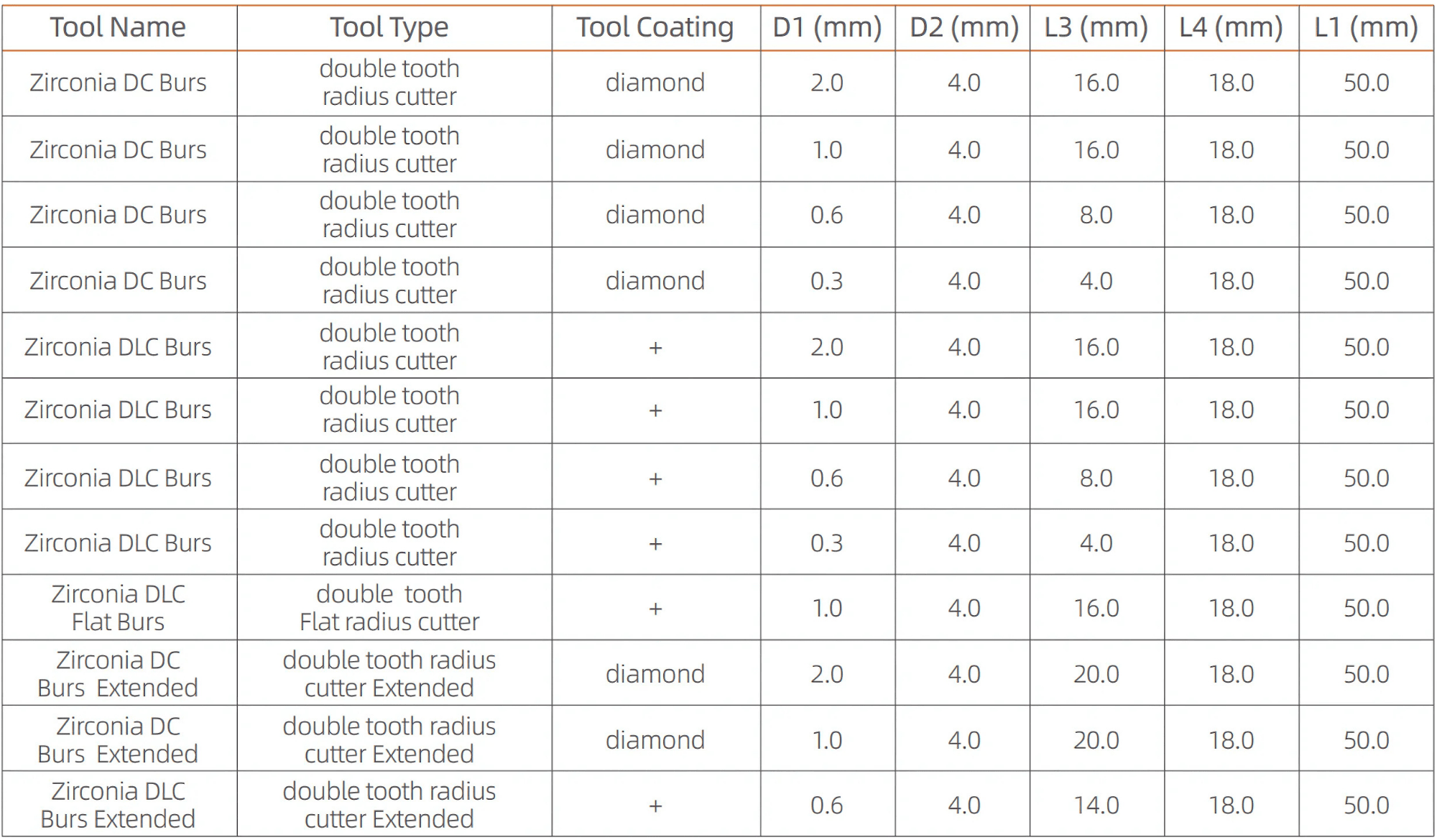

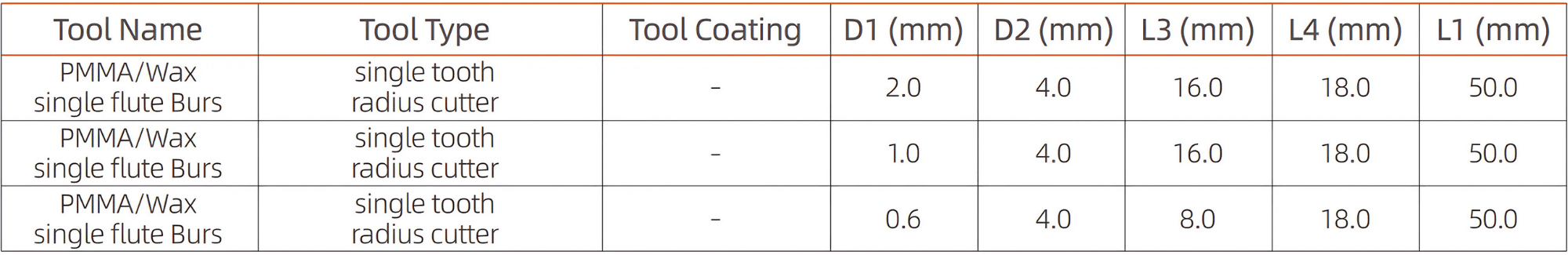

2 + 1 + 0.6+0.3 ( Φ4 calibration bur )

Round disc with Φ98, 30mm max for thickness

Φ4.0mm

UPCAM and Millbox

Network interface

UP3D is a high tech company and the few companies in the world that are capable of developing a full dental CAD/CAM solution including software and hardware, from scanning, designing, to Milling.

UP3D remains dedicated to our customers’ requirements for training and support as well as for innovative, high-quality products that perform reliably. We have native technical support to deal with any after-sales problems to ensure that you can use our products happily.

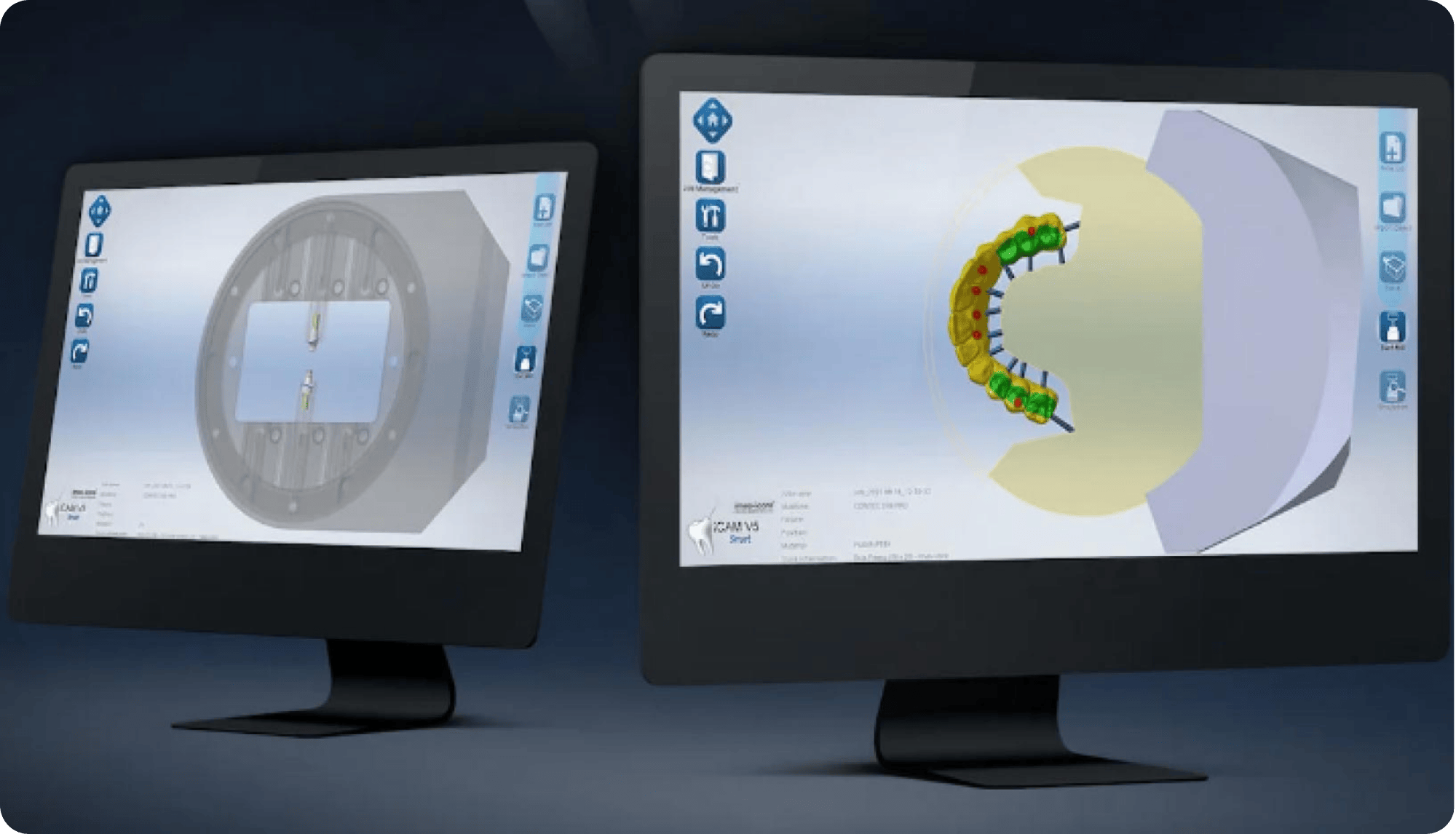

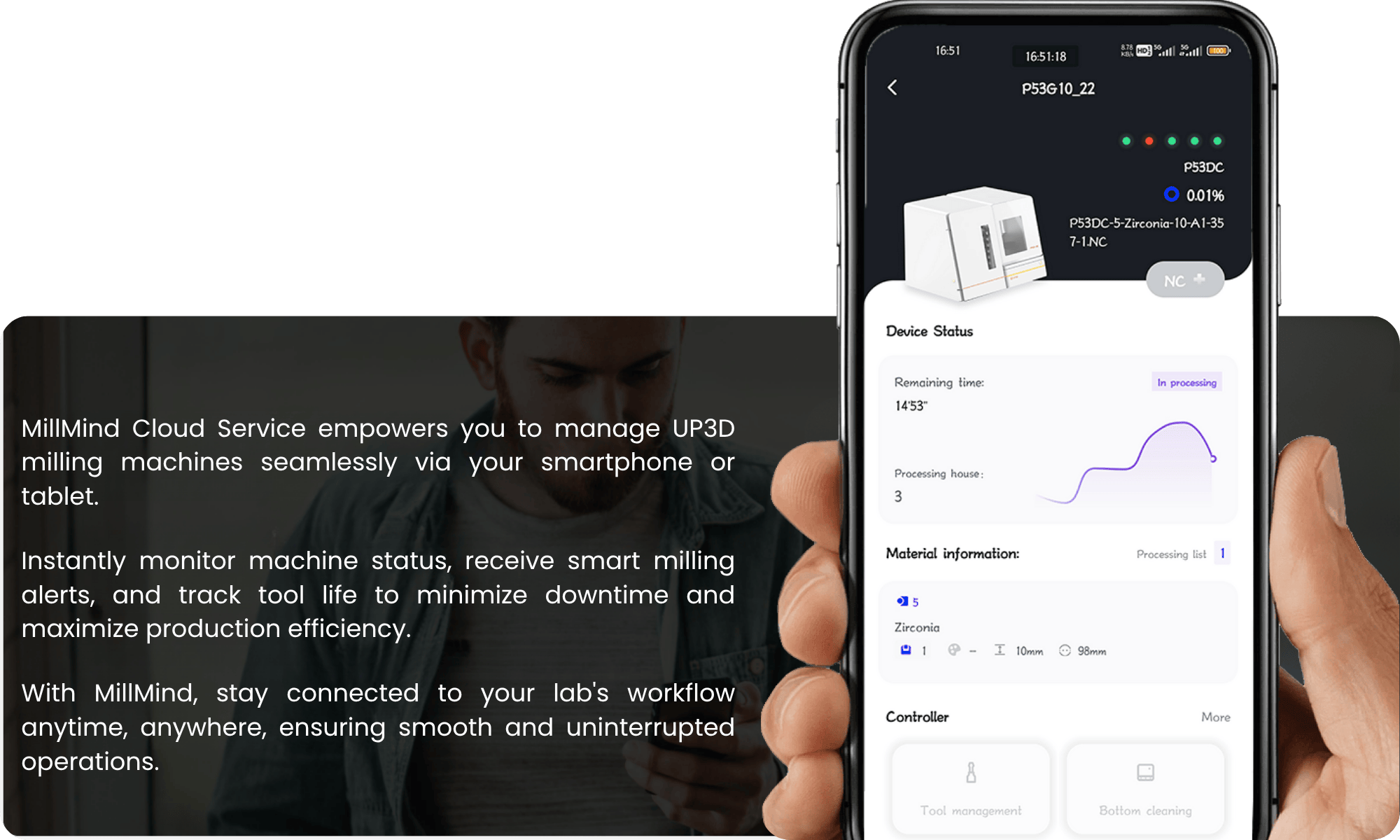

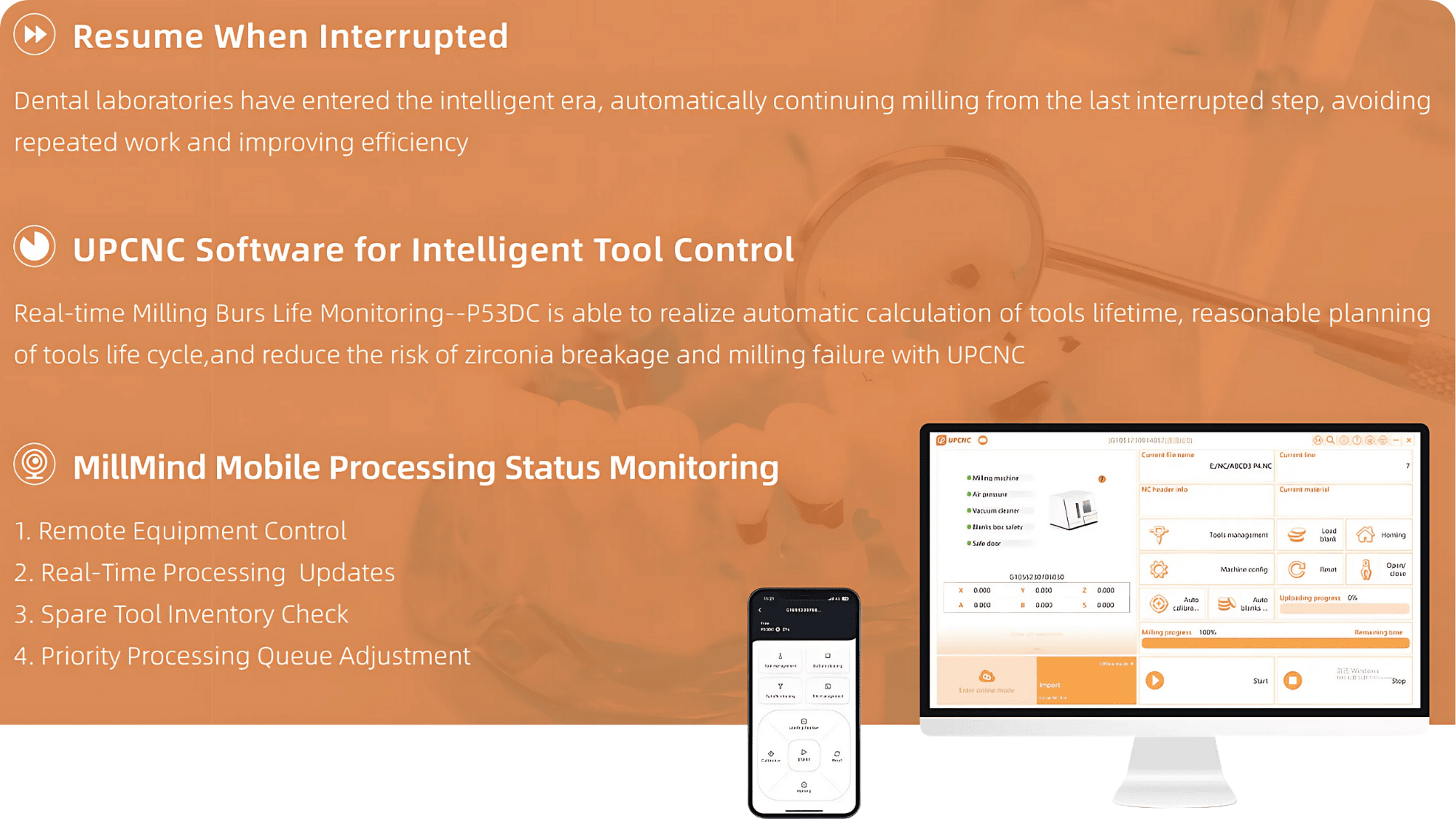

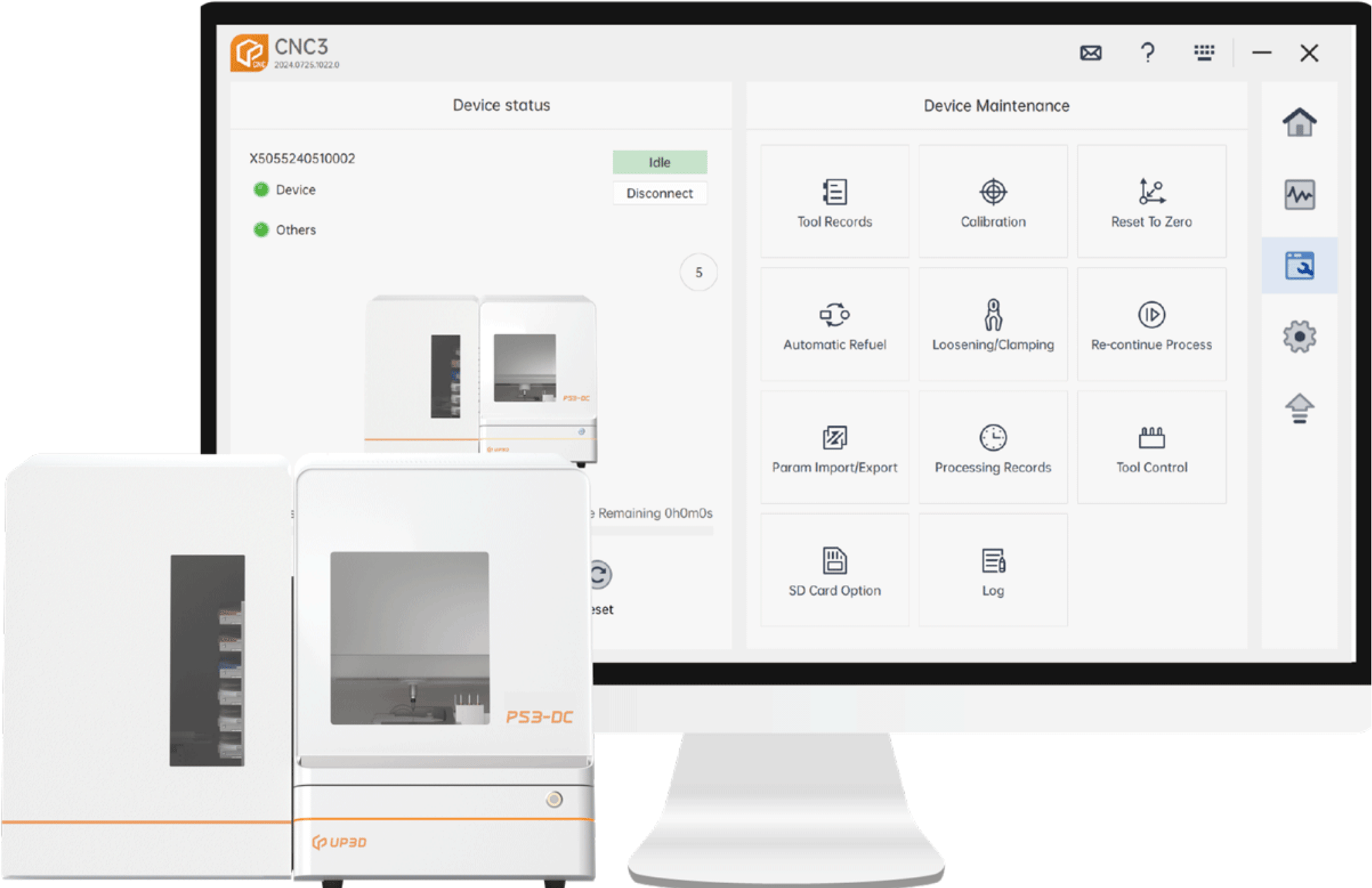

UPCNC

for UP3D Milling Machines

Take full control of your UP3D Milling machine with UPCNC. Effortlessly monitor tool usage, receive instant notifications on job completion, and be alerted to any errors-maximizing your productivity and ensuring smooth, uninter-rupted workflows.

UPCNC's intuitive, user-friendly interface makes it easy to operate, so you can focus on what matters most.

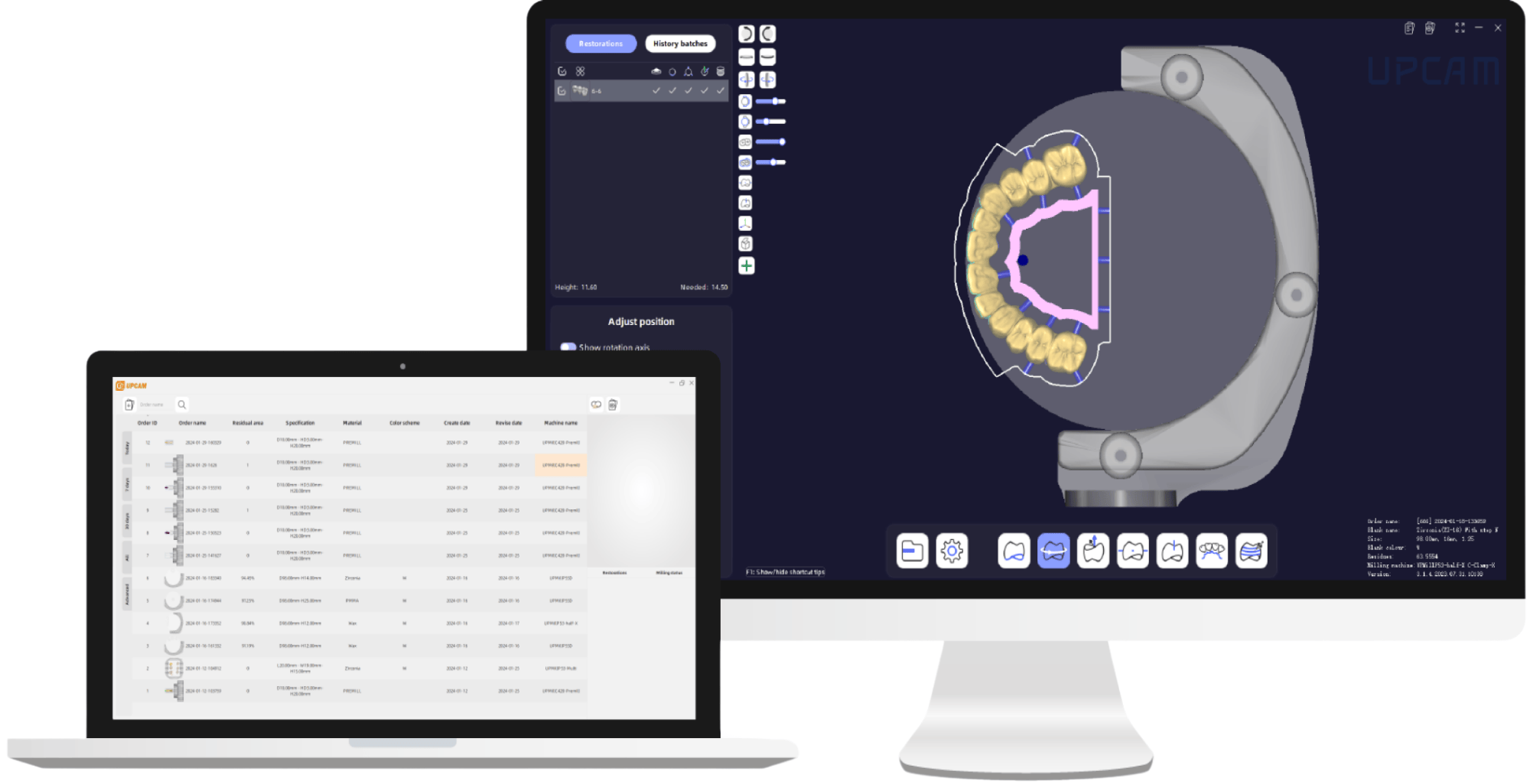

UPCAM

Smart Dental Nesting Software

Seamless Integration | Easy to Use

• Automatic Nesting

• Comprehensive Solution

• Toolpath Simulation

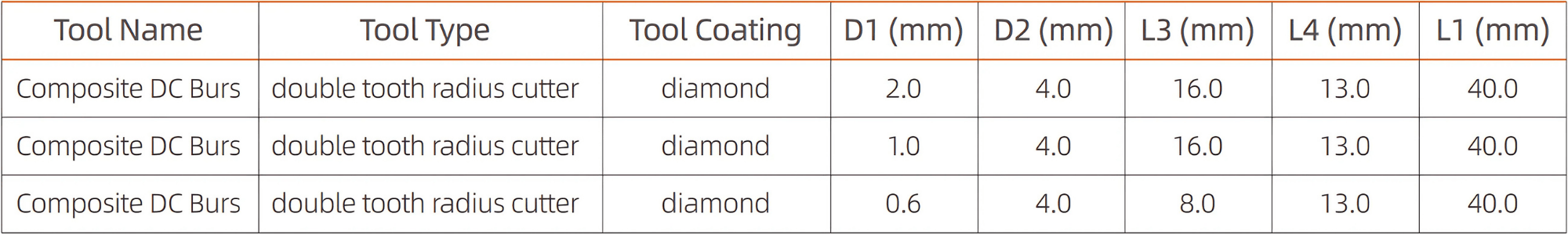

SPECIFICATIONS

GENERAL

Fields of application

- Dry machining

Materials

- Zirconia, wax, PMMA, PEEK, CoCr sintering metals, composite resin

Material Specifications

- Discs: height 10-30mm, diameter 98.5mm

- Blocks up to 40x20x20mm(Max)

Indications

- Crowns, anatomical crowns, screw-retained crowns, inlays, onlays, veneers, telescopic crowns, abutments, bite splints, full dentures etc.

Milling time

- Coping: Zirconia 10 minutes, Wax 4.5 minutes

- Crown: Zirconia 13 minutes, Wax 5.5 minutes

SPINDLE

General

- Spindle pneumatic tool change

Speed

- Up to 60,000 rpm

Max feed rate

- 3000mm/min

Tool holding

- Φ4.0mm

Power

- Peak power (Pmax): 900 watts • nominal power (S6): 500 watts • continuous power (S1): 350 watts

Spindle cooling

- Air Cooling

CONNECTION REQUIREMENTS

Compressed air

- Pressure: 0.5-0.8MPa, consumption: 60 L/min

Voltage

- AC 100V-240V, 50~60Hz

Dust extraction

- Filter level: M; Flow rate: 2500L/min

Data

- Ethernet port

DIMENSIONS & WEIGHTS

Dimensions

- 720×875×630 mm

Weight

- 138kg

HOLDER SYSTEMS

- BK-1 Clamp for Block Materials (optional)

BASE SYSTEM

Construction

- Machine bed made of solid cast aluminum body

Number of axes

- 5-axis simultaneous

Housing

- Steel, white high-gloss lacquer finish, main front housing: injection-molded

Rotary axes (A/B)

- A-axis: ±30°; B-axis: ±360°

Control unit

- Stepper drive system

Lighting

- LED lighting inside the working chamber

Power

- 0.55kW

AUTOMATION

Tool change

- Tool magazine for 11 tools, length measurement and tool breakage monitoring via precision measuring key

Disc change

- Material changer for up to 12 discs

ENVIRONMENTAL CONDITIONS

Operating temperature

- Between 10℃ and 35℃

Air moisture

- Below 80% (relative), non-condensing

SCOPE OF DELIVERY

CAM Software

- UPCAM

FAQ's

We've put together a list of answers to the most pertinent questions.

What makes UP3D dental Milling machines the right choice for my practice?

UP3D dental Milling machines combine precisie performance with user-friendly features, making them ideal for efficient and accurate dental work. Our machines are built to be durable and require minimal maintenance, while advanced automation and seamless compatibility ensure a smooth reliable workflow. With UP3D, you're choosing quality, innovation, and dependable results every time.

Why should I buy a dental Milling machine that only does dry or wet Milling?

At UP3D, we believe in maximizing performance and longevity. By dedicating each model to either dry or wet Milling, we optimize each machine for its specific purpose, reducing the choose the right machine for your specific needs with confidence.

Can I use this machine with my current CAD/CAM software?

Yes, the P53DC is designed to integrate seamlessly with most popular CAD/CAM software systems, allowing you to incorporate it into your existing workflow without any major adjustments. This compatibility ensures that you can get started with minimal training or transition time.

After purchase, will I be provided with a course to learn how to use the machine?

Yes, we offer comprehensive training to ensure you and your team are comfortable operating the P53DC. This includes hands-on training sessions, access to online tutorials, and ongoing support. Our goal is to help you maximize the machine's capabilities from day one, so you can make the most of your investment.

What kind of warranty and support is included?

The P53DC comes with a standard one-year warranty, covering parts and labor. Our global support team and local partners are ready to assist with any questions or technical issues, ensuring that your machine operates smoothly over its lifetime.

DOWNLOAD FILES