UP3D - P53 Smart dental 5-axis milling unit 110v # P53

15581_f.jpg)

15580_f.jpg)

15579_f.jpg)

Description

UP3D

P53 Smart Dental 5-axis Milling Unit

A Smarter, More Efficient Solution for Dental Laboratories

The P53 Five-Axis Intelligent Dental Milling Machine is a cutting-edge dry Milling device designed to revolutionize dental prosthesis production. Featuring an advanced intelligent control system within a unified, durable structure, this machine ensures streamlined and scalable manufacturing for dental labs.

With its powerful integration of smart technology, the P53 provides efficient, dust-proof Milling with extended durability, offering a hassle-free and long-lasting solution for dental laboratories. For even greater performance, the V10 Smart Dental Vacuum can be added, boosting efficiency and cleanliness. A 2-year warranty further enhances reliability and peace of mind.

Dust-Proof Slides for Extended Durability

The P53 Five-Axis Dental Milling Machine incorporates innovative dust-proof slide technology that effectively seals its internal components from dust and airborne contaminants. This advanced feature dramatically reduces the need for regular maintenance, enhancing operational efficiency while extending the lifespan of the machine. Dental labs can now benefit from a more reliable, durable, and low-maintenance Milling experience, ensuring long-term performance and reduced downtime.

Effortless Material Switching with Custom BK-1 Clamps

The advanced BK-1 clamp system is designed to facilitate rapid material changes, allowing for seamless transitions between discs and blocks in mere seconds. This innovation optimizes production efficiency, enabling dental labs to enhance workflow speed and reduce downtime, ensuring a smooth and efficient Milling process.

Precision 90° Vertical Milling for Life-like Restorations

The P53 Five-Axis Dental Milling Machine utilizes advanced synchronous technology for precise 90° vertical Milling, supported by a 0.3mm micro-carving cutter. This cutting-edge combination ensures the production of high-quality dental prosthetics with natural, life-like aesthetics, allowing for efficient and accurate restoration every time. Dental labs can consistently deliver superior, realistic outcomes for patients through this intelligent Milling solution.

Smart Remote Control for Enhanced Milling Management

The MillMind software offers advanced remote control capabilities, providing users with smart Milling reminders and real-time monitoring of tool life. This intelligent solution ensures efficient production oversight, enabling dental laboratories to optimize their workflow, reduce machine downtime, and ensure seamless operations with greater precision.

Precision and Stability with One-Click Smart Calibration

The innovative one-click calibration feature simplifies operations by automatically enhancing the machine’s accuracy and stability. This intelligent function significantly reduces Milling errors, minimizes material waste, and boosts overall production efficiency. Dental labs can consistently achieve high-precision dental prosthetics with unmatched quality and reliability through this streamlined, user-friendly solution.

01

C-Clamp Design

The innovative C-clamp expands buccal Milling space, enhancing material layout and edge utilization. This allows for cost-effective, high-quality dental restorations through maximized material use.

02

Smart LED display strip

The external LED strip synchronizes in real-time to visually track processing progress, eliminating the need for manual checks and enhancing overall production efficiency.

03

CNC multi-machine control

A single CNC software can manage multiple machines, monitoring real-time status across devices. This saves valuable desktop space and computing resources.

04

Resume Milling at Breakpoint

The software automatically continues Milling from the last interrupted step, eliminating repeated work. This feature boosts efficiency by at least 80%, saving time and resources.

05

Tool Life Monitoring

Integrated UPCAM technology automatically calculates tool wear, enabling strategic planning to reduce the risk of porcelain breakage and processing failures for consistent, high-quality results.

Specification

Model

Dimension

Weight

Input Voltage

Maximum Power

Spindle Power

Number of Axes

Mil'ling Range

Mil'ling Type

Max Spindle Speed

Max Feed Rate

Tool Quantity

Tool Change Method

Spindle Cooling

Materials

Mil'ling Time

Material Size

Spindle Clamping Diameter

CAM Support

Data Transmission

P 53

443.5*718*628.5mm

87kg

AC 100-240V

1.1KW

0.35KW (max)

Five-axis simultaneous

X/Y/Z: 167/200/90mm, A:±30° B:±360°

Dry mil'ling

40,000rpm

3000mm/min

11

Automatic (air pressure > 0.5MPa)

Compressed air (air pressure 0.15~0.20MPa)

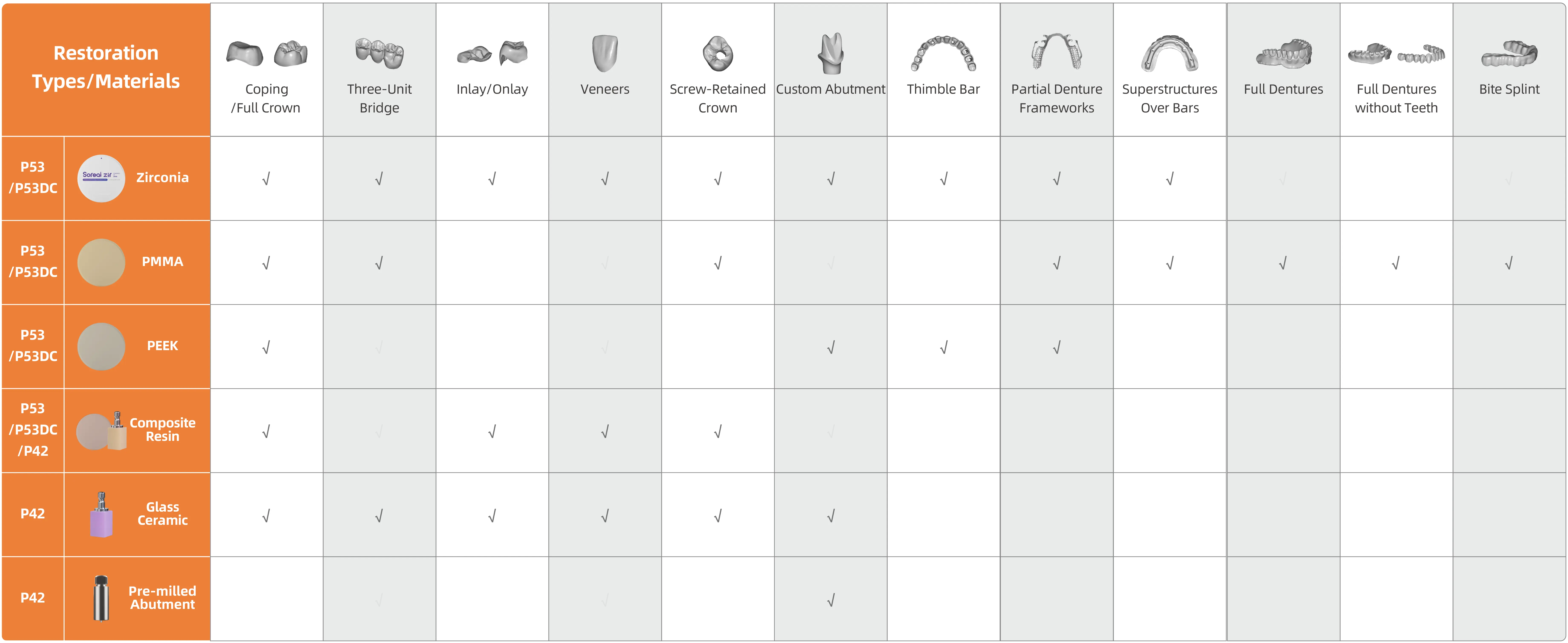

Zirconia, wax, PMMA, PEEK,

cobalt-chromium soft metal, composites

cobalt-chromium soft metal, composites

Coping: Zirconia 10 minutes,

Wax 4.5 minutes Full crown: Zirconia 13 minutes,

Wax 5.5 minutes

Wax 4.5 minutes Full crown: Zirconia 13 minutes,

Wax 5.5 minutes

Discs: height 10-30mm, diameter

98mm Blocks up to 40*20*20mm

98mm Blocks up to 40*20*20mm

Φ4.0mm

UPCAM, Millbox

Network interface