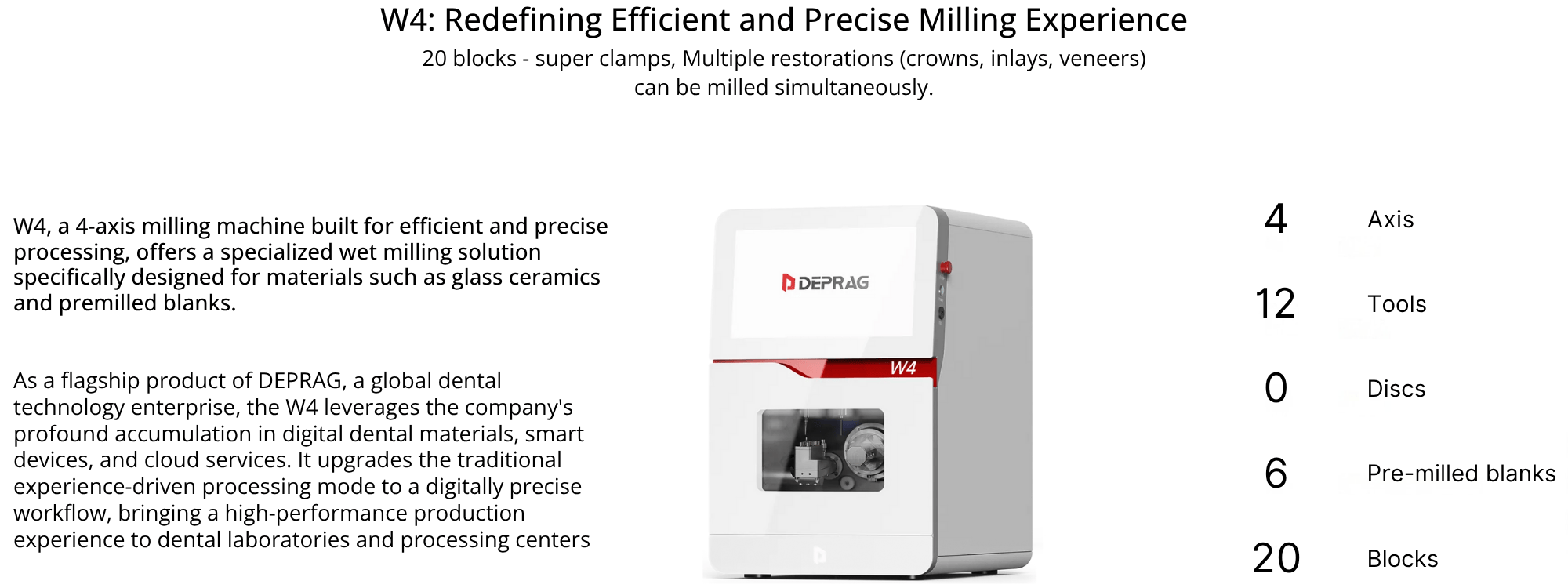

DEPRAG - W4 WET 4 axis Dental Milling unit Set - Water Cooling System - Tank - Cabinet - # DEP-0005

14157_f.jpg)

Description

Download the brochure for all details.

Download ↓

HIGHLIGHTS

Batch Processing, Enhanced Efficiency

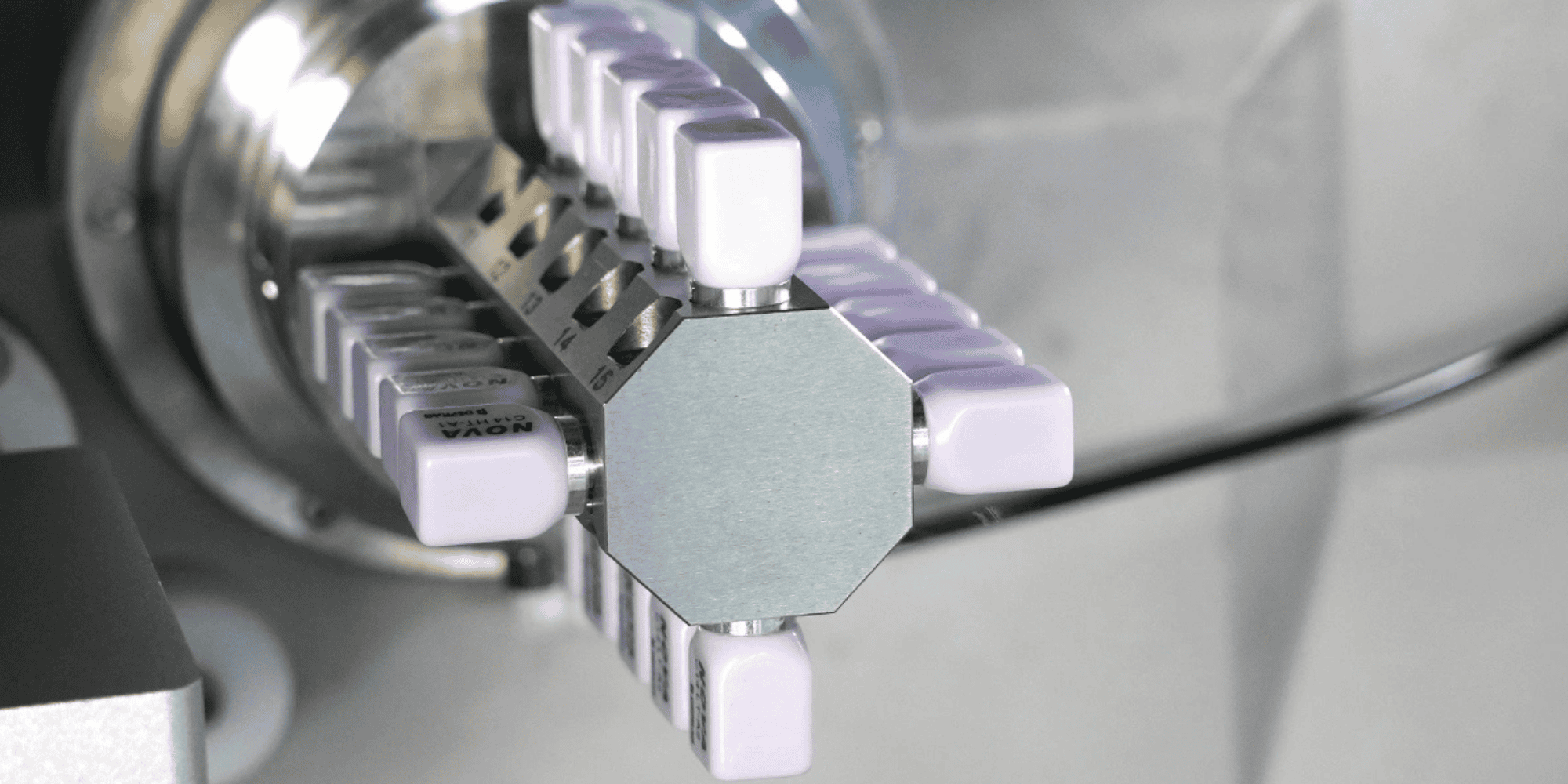

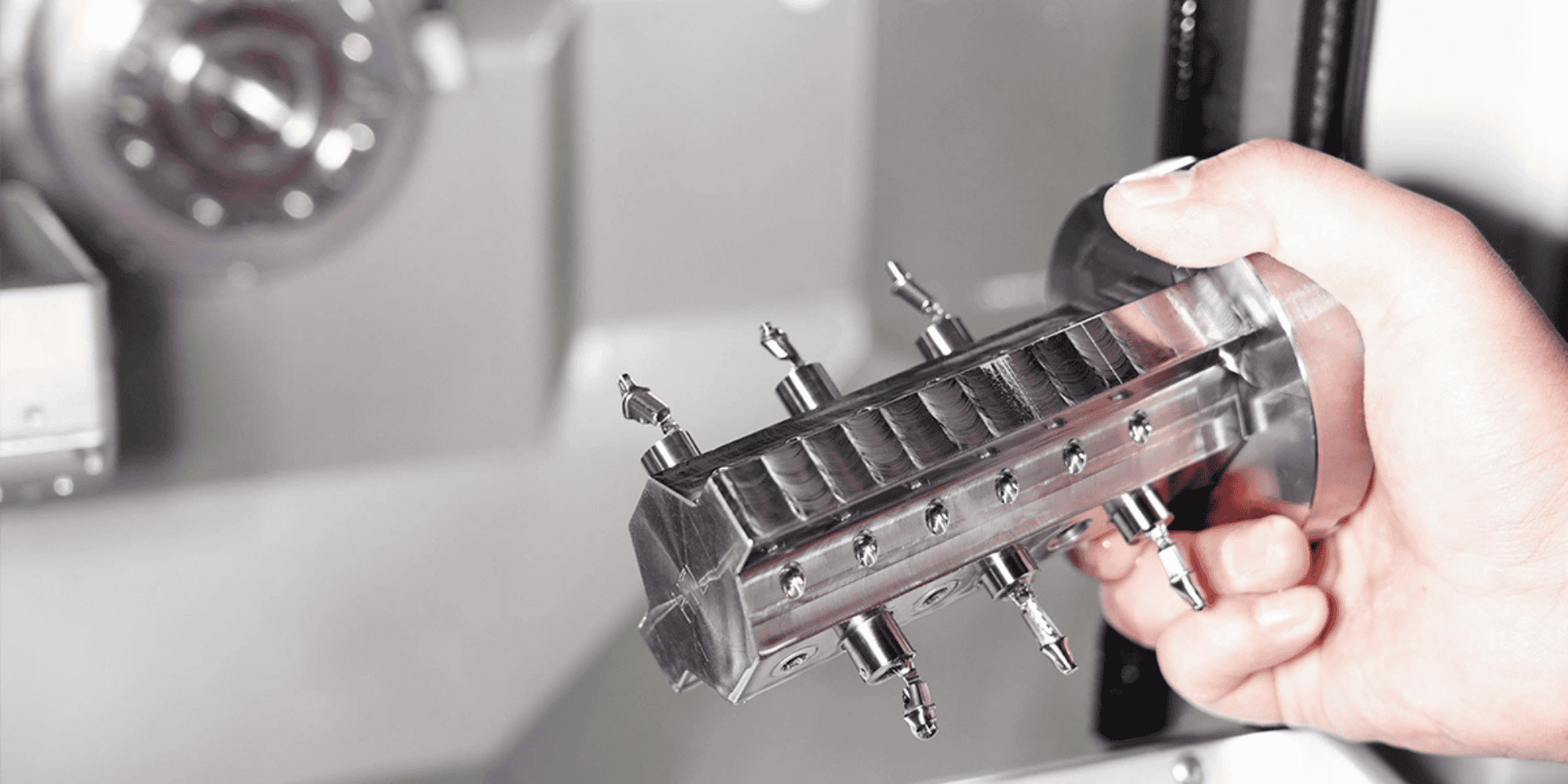

The 20-position, four-sided distributed super holder and zero-point change System support processing 20 blocks of material at one time, eliminating the need for frequent shutdowns for material replacement and significantly shortening the production cycle .

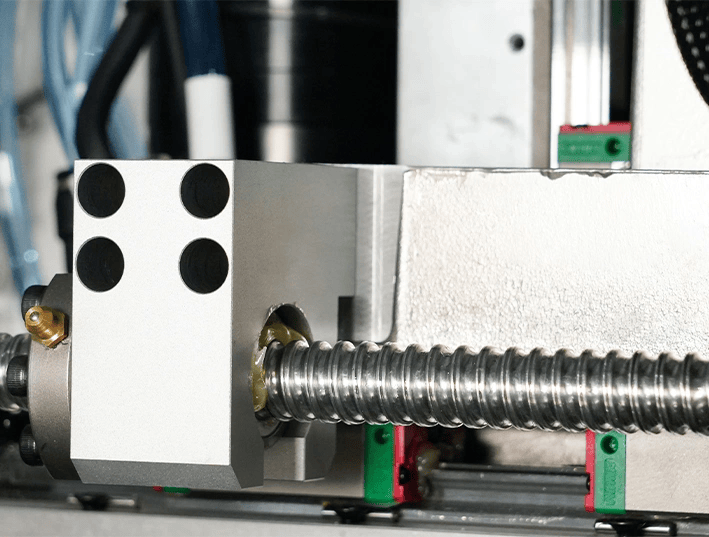

Ultra-high Precision, Reduced Waste

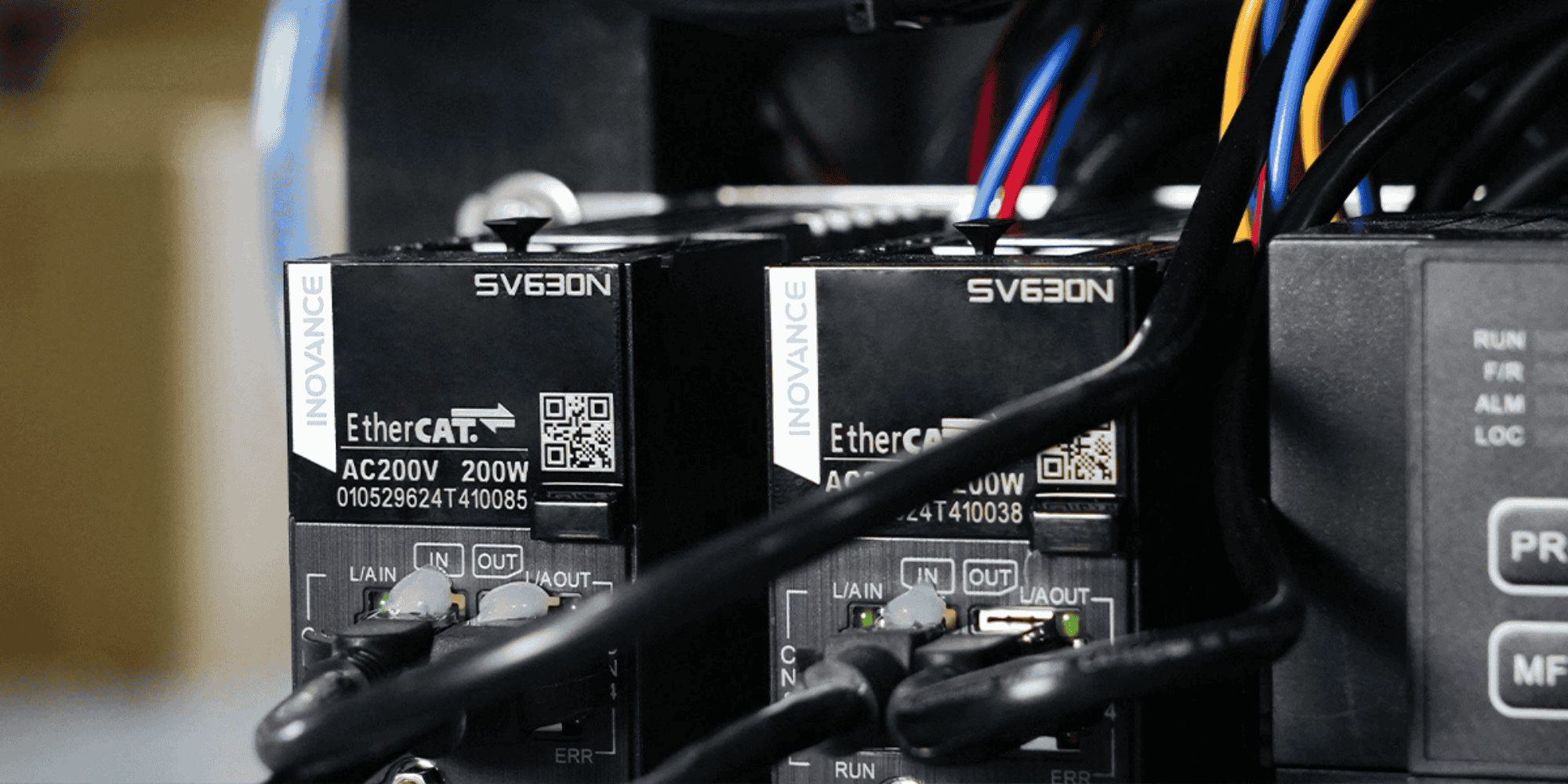

Equipped with a C5 grade high-precision ball screw, P grade guide rail, and a high-resolution servo control System, it boasts a repeat positioning accuracy of 5 μm and an overall processing accuracy of up to 0.01 mm. The built-in automatic calibration function, combined with a guided calibration process, directly reduces material waste by 15%, ensuring that every piece of material is converted into effective output .

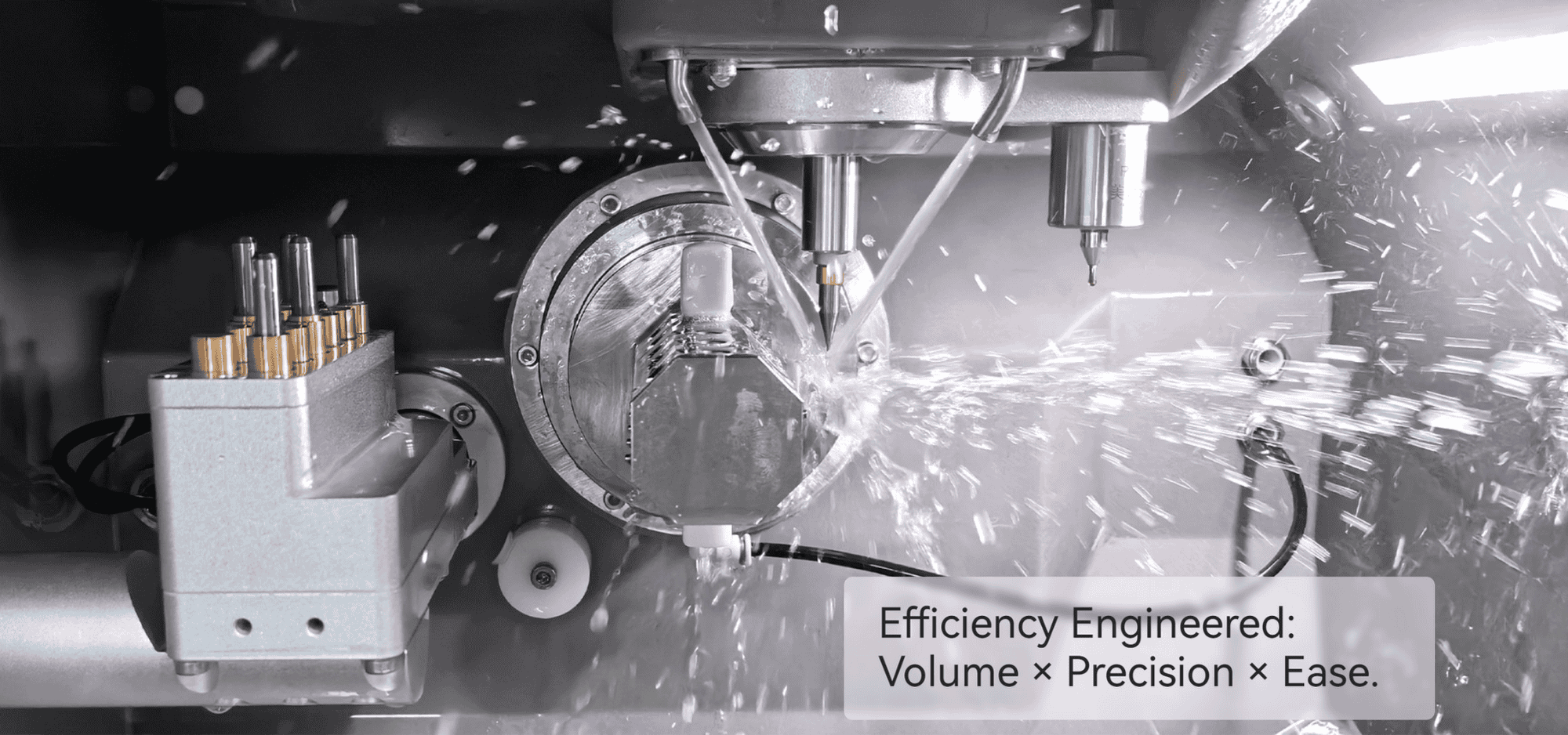

Stable and Reliable, Reduced Loss

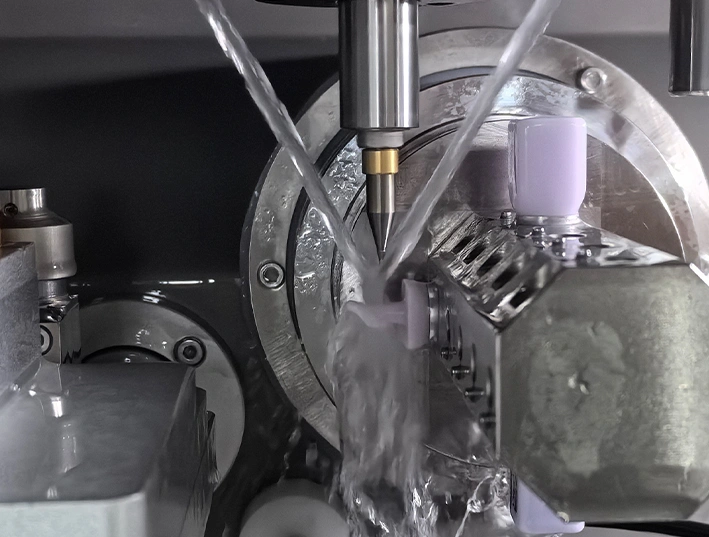

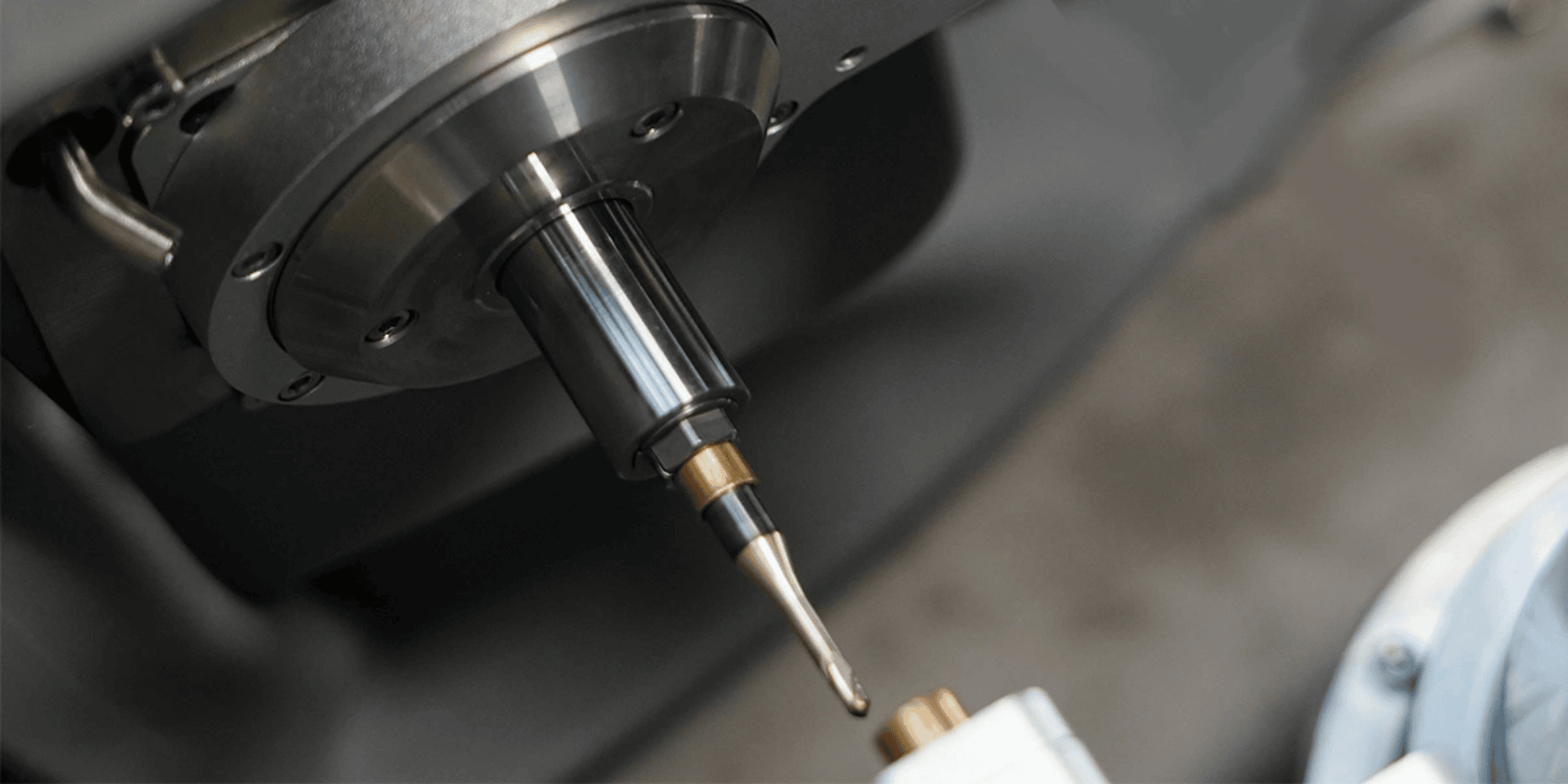

The 2.5kW spindle (Φ62mm) provides powerful performance, and the professional Water-cooled System extends the service life of the machine. The integrated casting body ensures stable Milling without vibration, keeping the output quality consistent .

Extremely Easy to Operate, Quick to Master

The 19.5-inch screen paired with the Win10 System enables agile and intuitive operation. The intelligent tool grouping management and automatic tool change functions reduce manual intervention, and with guided operation that requires minimal training to master, it lowers labor costs .

Wireless Freedom, Flexible Adaptation

The fully wireless remote function supports device control and file transfer, requiring no external wiring. It can be easily integrated into various production environments, adapting to diverse workflows .

FEATURES

HIGH PRECISION

• C5 grade high-precision ball screw

• P grade guide rail and high-resolution servo control System

• Hybrid ceramic ball bearings (<3μm concentricity)

EASY TO USE

• 19.5-inch screen, agile operation;

• Intelligent management of tool grouping

• Automatic tool change;

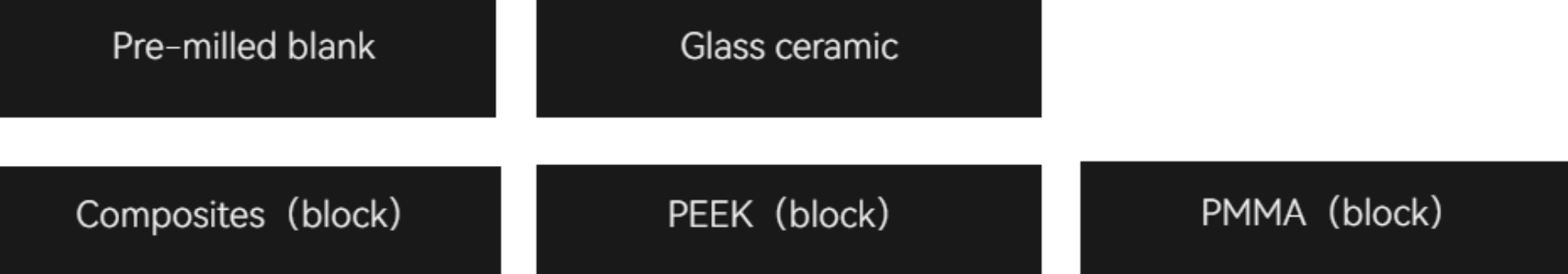

MACHINABLE MATERIALS

APPLICATIONS

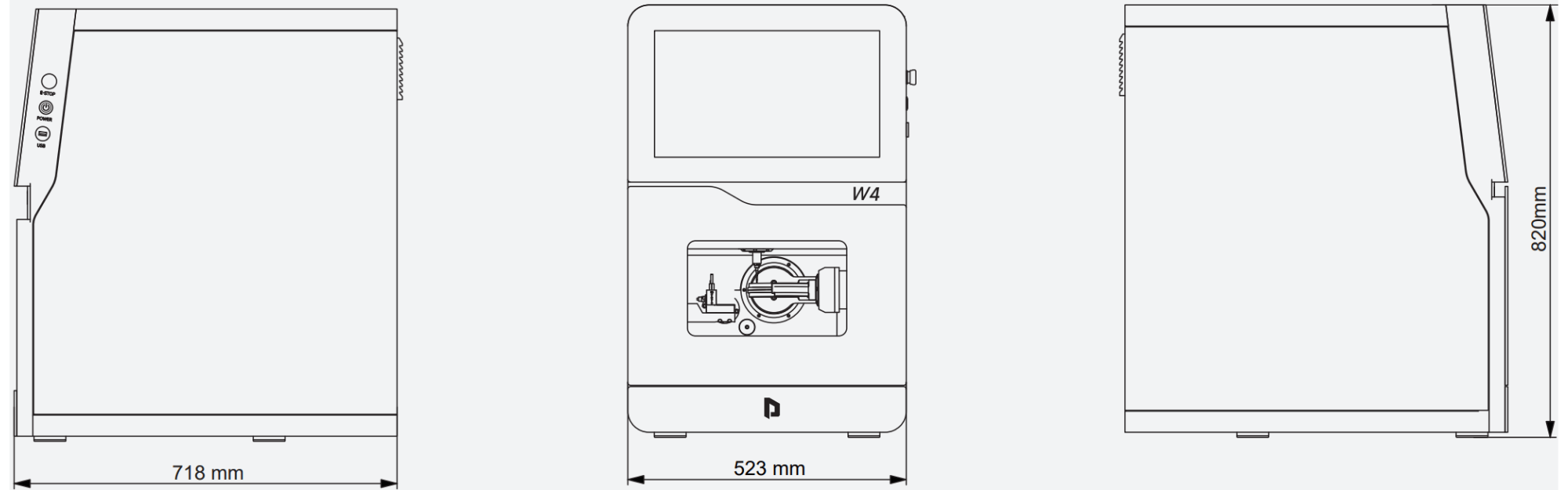

EQUIPMENT PARAMETERS

GENERAL

Processing mode

Millable material

Applications

Power

Dimension

Weight

Air supply pressure

Air flow

Water Tank capacity

WET

Glass ceramics, PMMA, PEEK, Pre-milled blank

Crown | Bridge, Veneer, Inlay | Onlay, Abutment

220V/3.2kW

523x718x820 mm

130 kg

>0.5 MPa

>90 L/min

10L

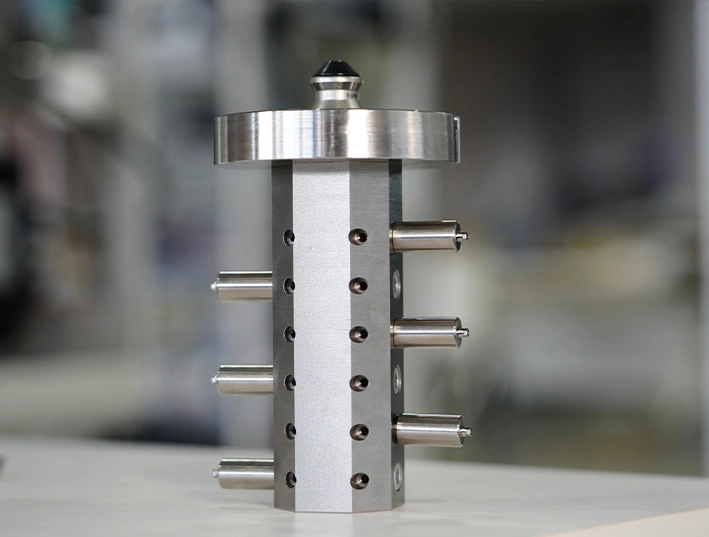

STRUCTURE PARAMETERS

Basic construction

Number of axes

Rotary axis B-axis

Tool

Aluminium

4

360°

12

SPINDLE

Speed

Power

Positioning/Repositioning accuracy

Collet

Cooling method

60,000 rpm

2.5kW

0.01/ 0.005 mm

Φ6 mm

Water Cooling

OTHERS

All models

North America model

Clamps

CE

FCC

Pre-mill Abutment holder/Block holder