DEPRAG - D5 Max DC DRY Disc Changer (8) Dental Milling unit Set - Self Calibration - Remote assistance - # DEP-0008

14161_f.jpg)

14160_f.jpg)

14159_f.jpg)

14158_f.png)

Description

Download the brochure for all details.

Download ↓

HIGHLIGHTS

Completely automated, saving on labor costs

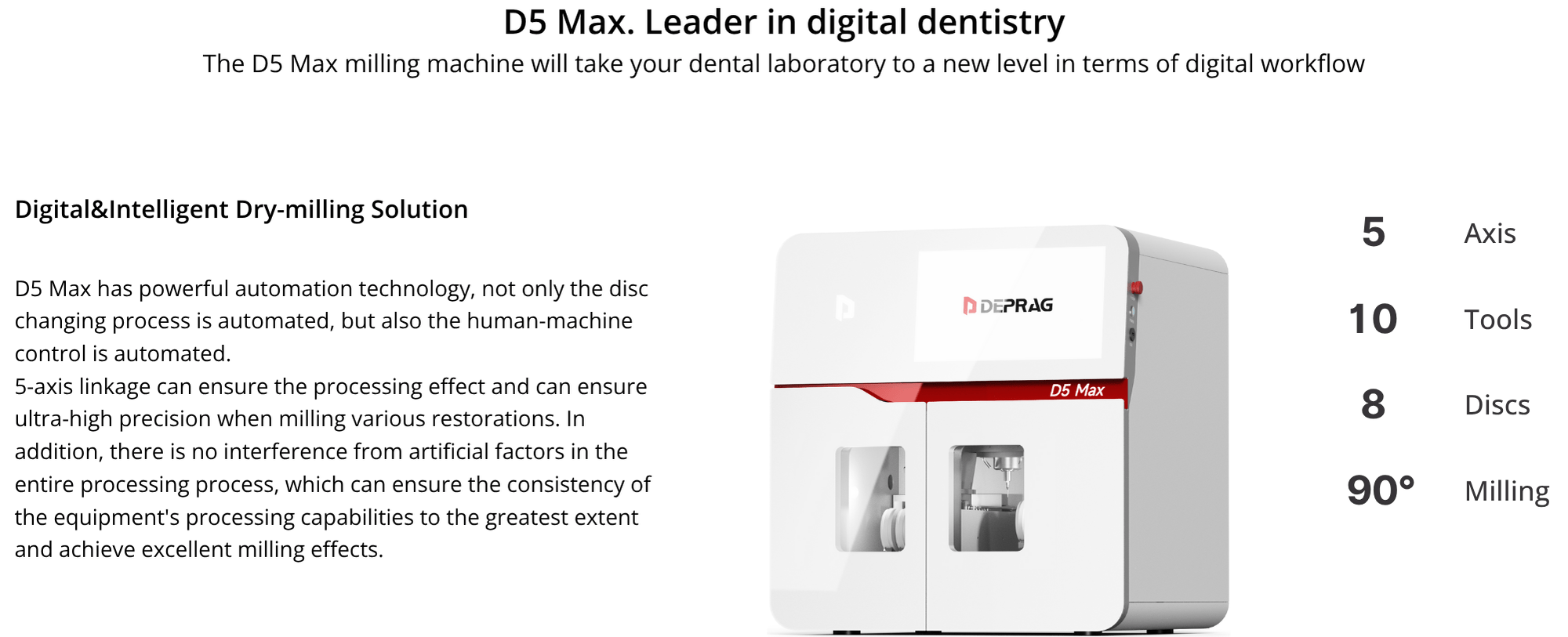

The D5 Max is equipped with powerful automation technology, which not only automates the tray changing process but also the human-machine control. Multiple devices can be controlled remotely, and the entire process is digitalized and intelligent, reducing manual intervention.

Multiply efficiency, saving time

The automatic disk changing function of D5 Max enables the equipment to work 24 hours a day, greatly improving the output and capacity, fundamentally saving time and improving work efficiency. After testing, the capacity of D5 Max is 1.6 times that of ordinary manual Disc changing equipment.

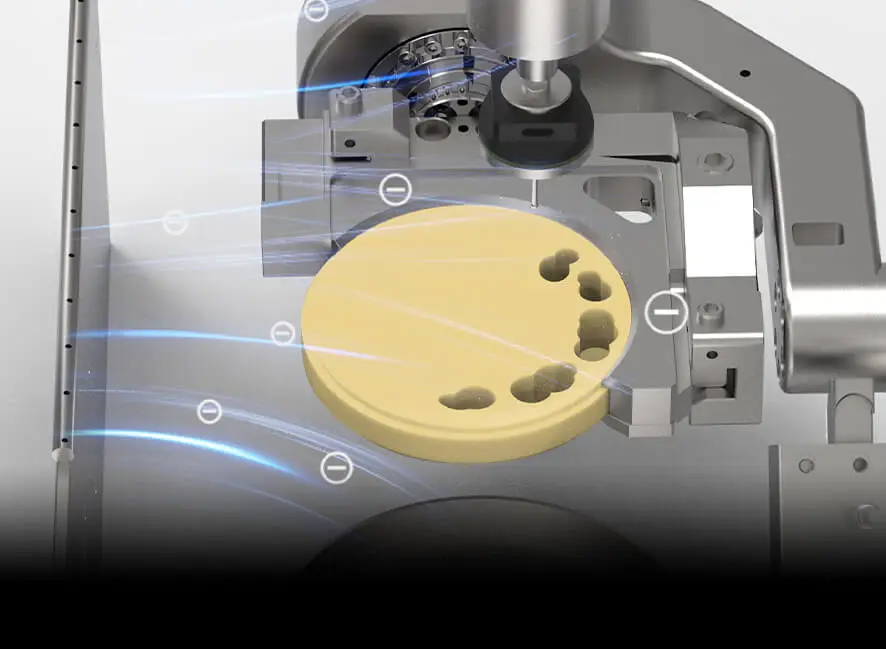

Precise operation, stable operation

D5 Max adopts RFID tray intelligent identification technology and a a tray-changing module with servo electric claws and a flexible mechanical structure to ensure the accuracy and success rate of automatic tray replacement.

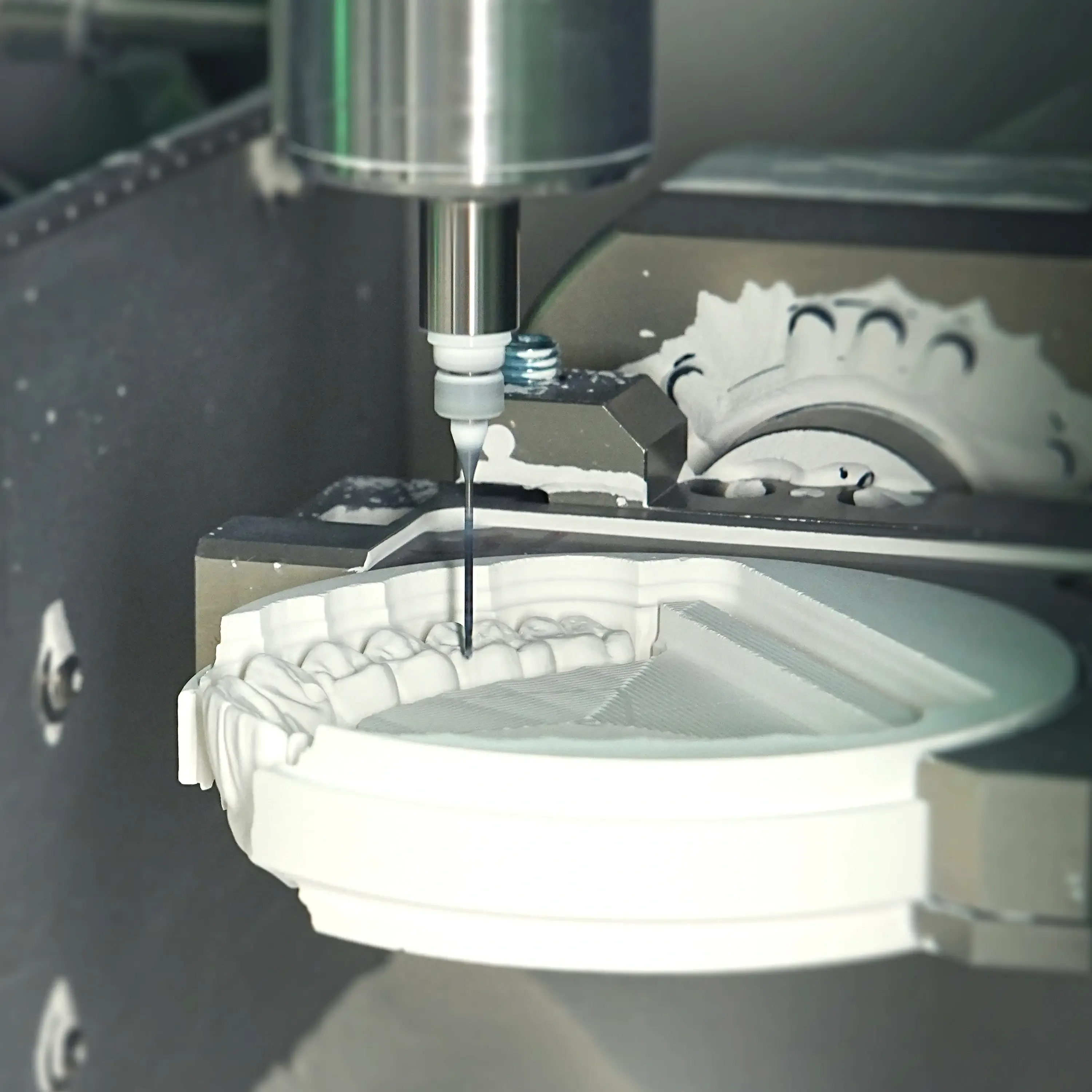

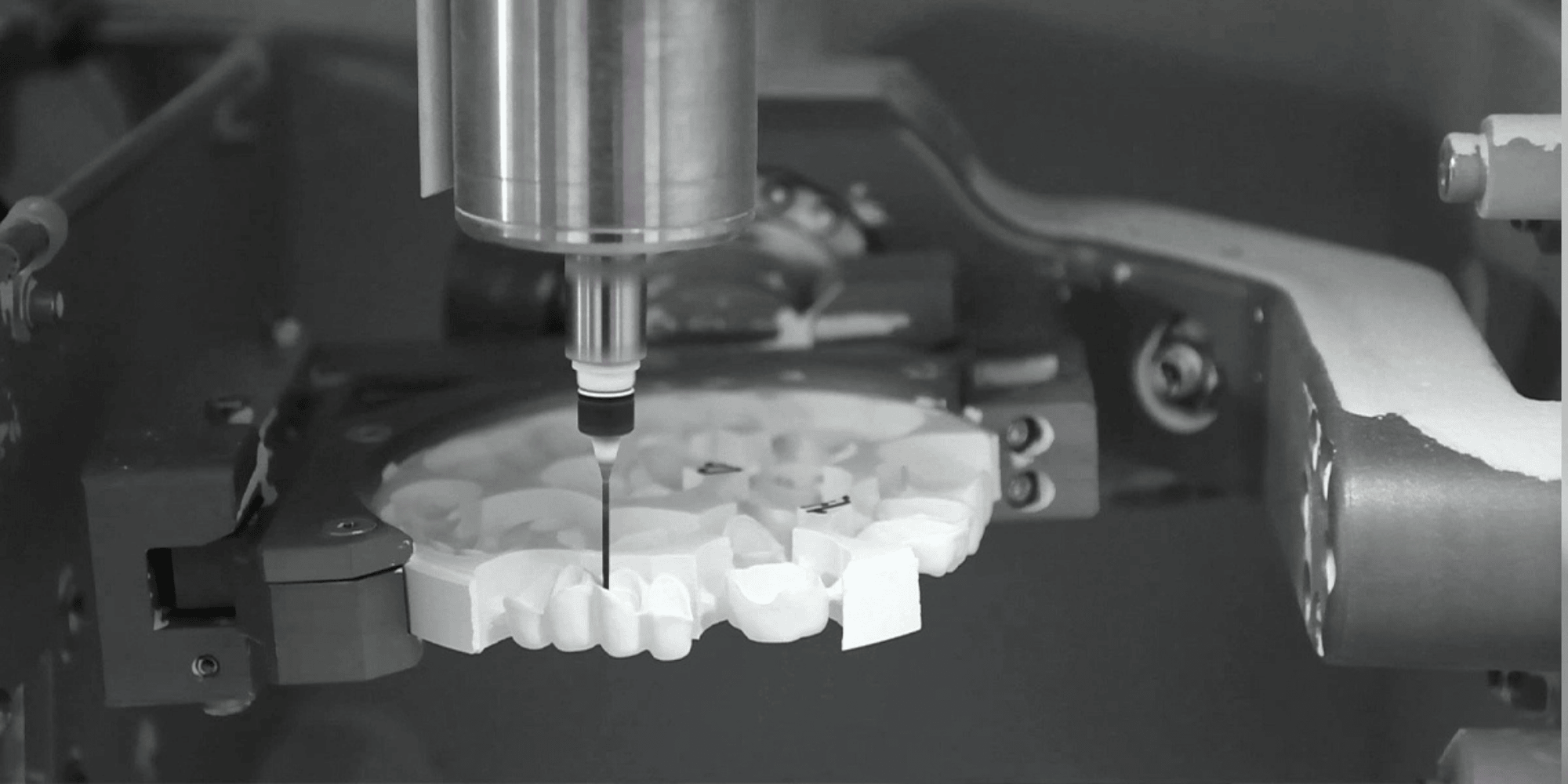

Excellent Milling results

D5 Max chooses high-quality spindles and servo motors from INOVANCE as the the crucial components of the equipment, ensuring the Milling accuracy and stability of the equipment.

FEATURES

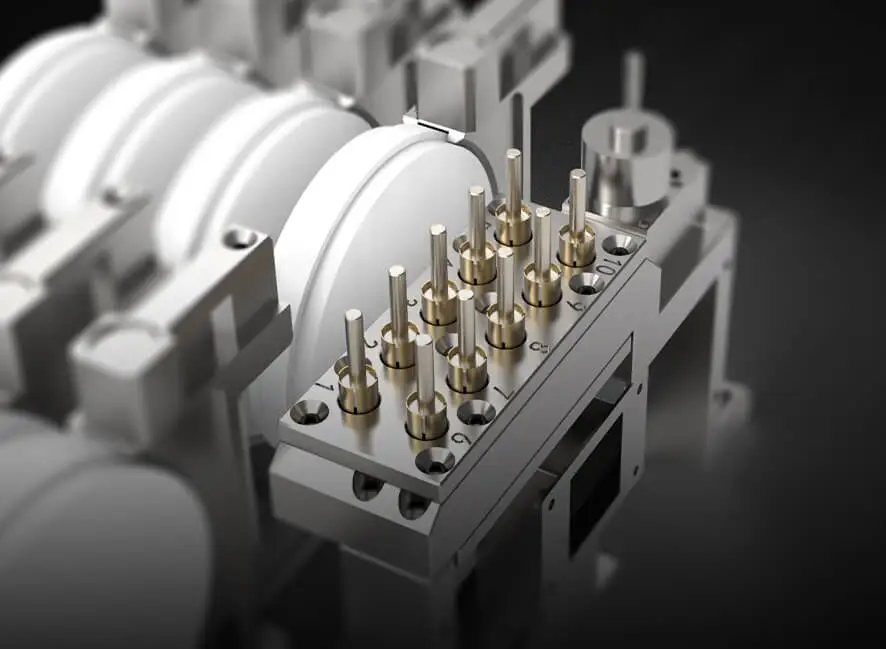

UNATTENDED

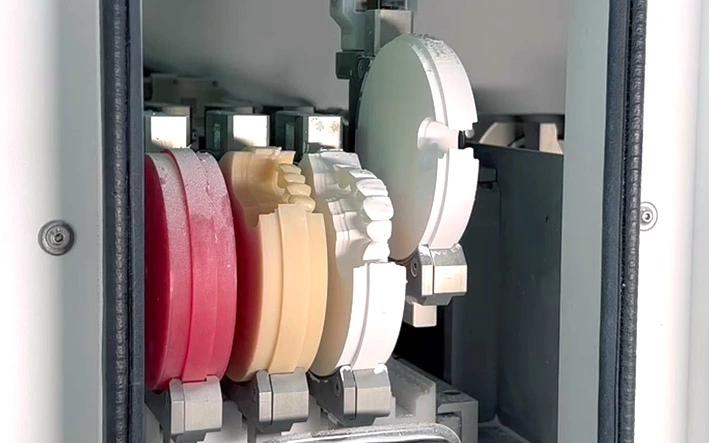

• 8-slot, realize fully automatic switching of material discs.

• RFID identification system.

• Win 10 system, Remote file transfer

• Remote control.

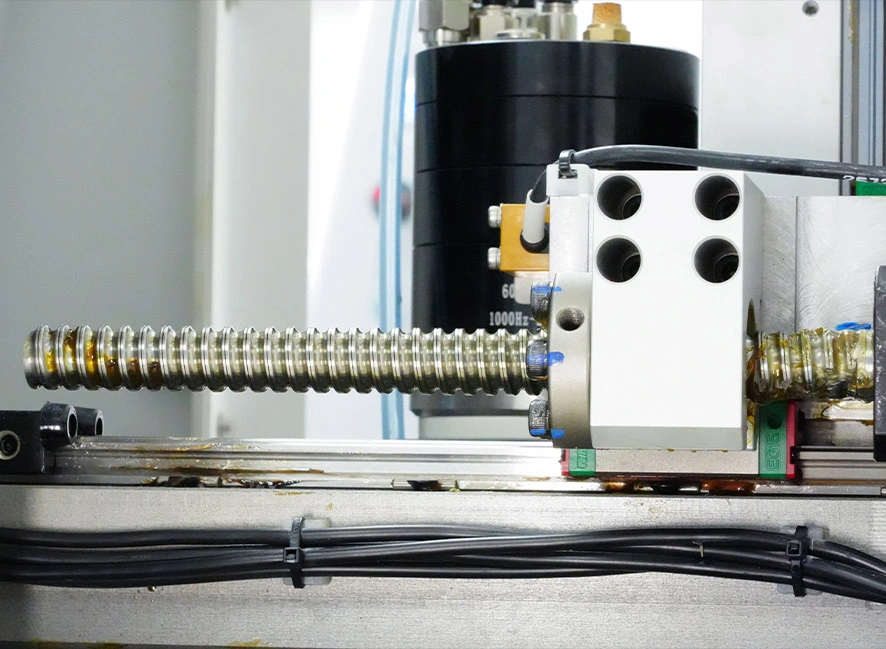

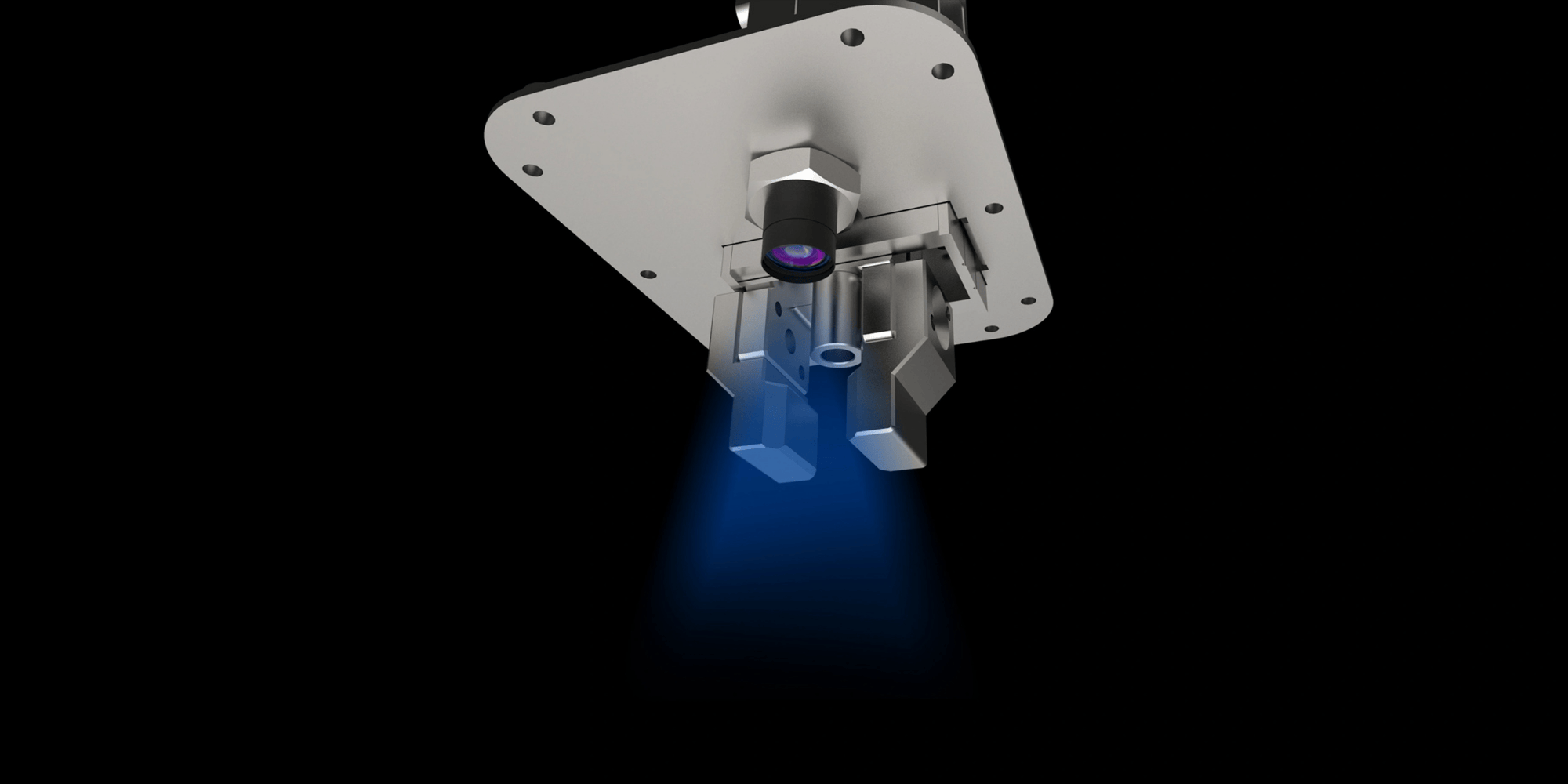

HIGH PRECISION

• C5-grade high precision ball screw

• H-grade linear guide

• 62mm diameter, 60000rpm spindle

• Repeat positioning accuracy 5μm

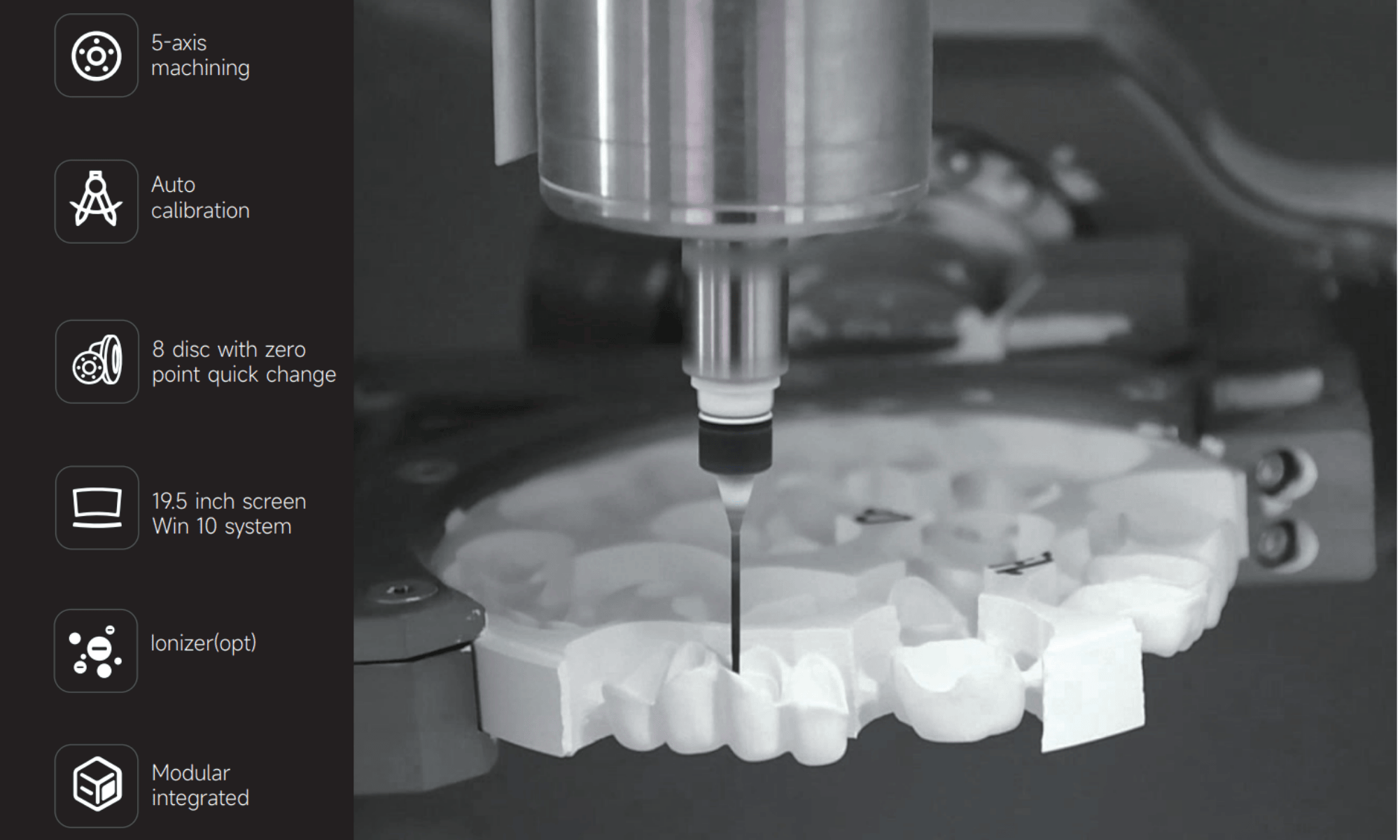

MACHINABLE MATERIALS

APPLICATIONS

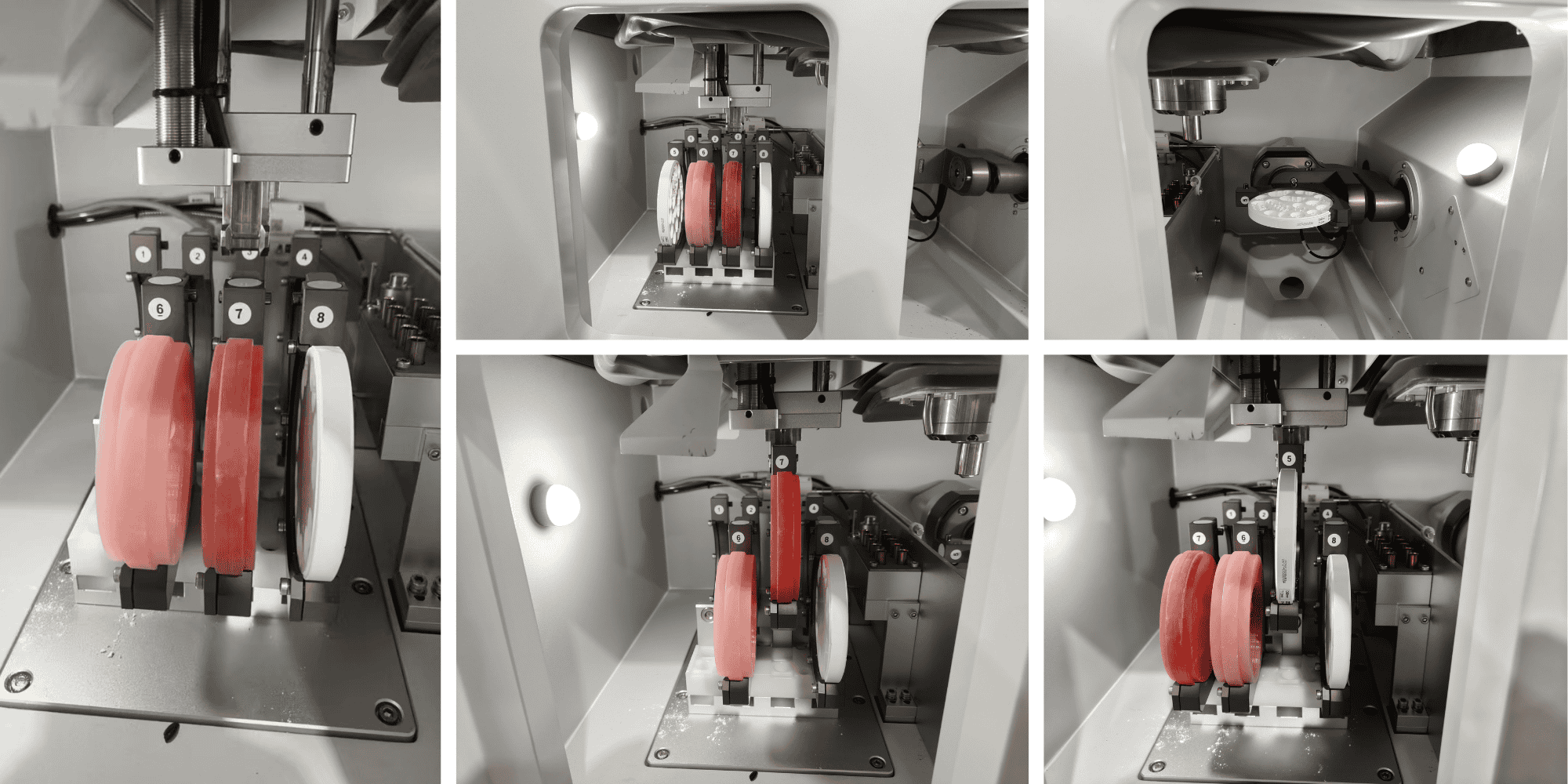

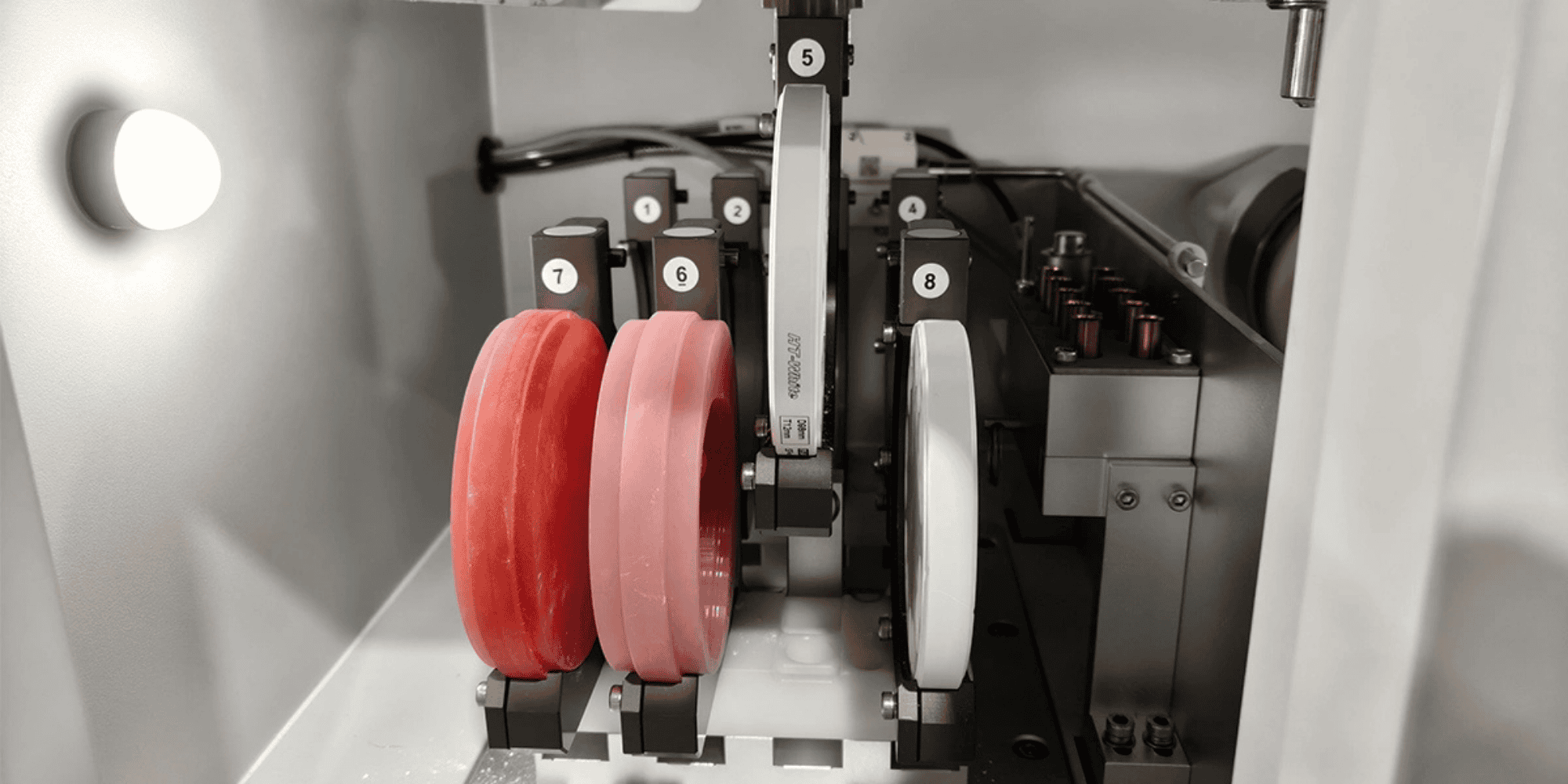

INTERNAL PICTURES

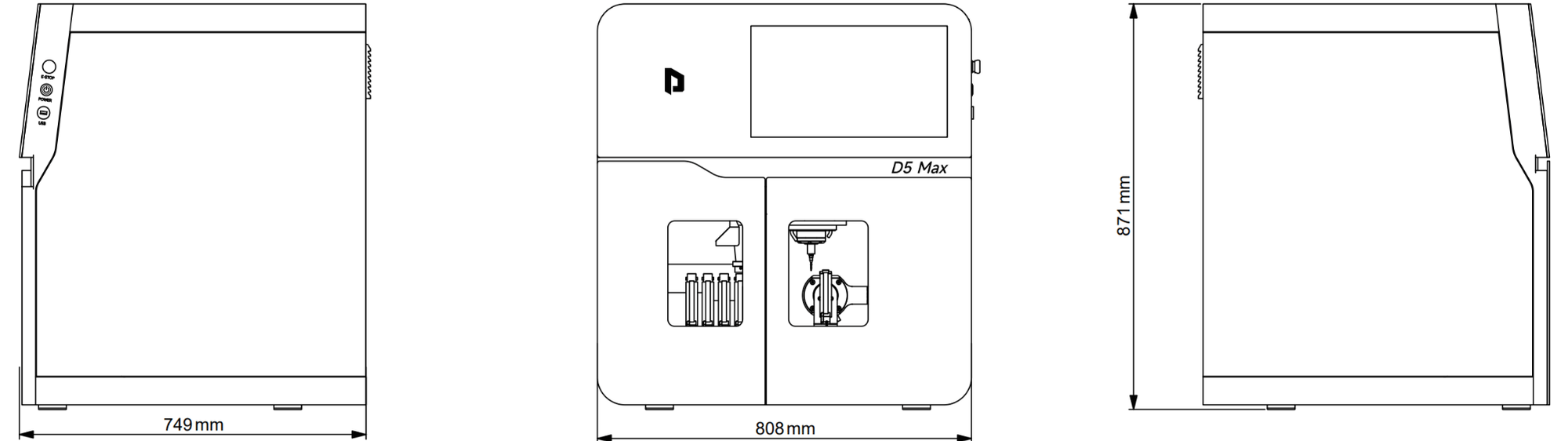

TECHNICAL PARAMETERS

GENERAL

Processing mode

Millable material

Applications

Power

Dimension

Weight

Air supply pressure

Air flow

DRY

Zirconia, PMMA, Wax, PEEK, Composite

Crown | Bridge, Veneer, Inlay | Onlay, Abutment, Denture, Screw-retained bridge, Model cast, Surgical guide

220V/2.5kW

808 × 749 × 871 mm

180 kg

>0.5 MPa

>200 L/min

STRUCTURE PARAMETERS

Basic construction

Number of axes

Rotary axis A-axis

Rotary axis B-axis

Tool

Aluminium

5

+30°~-30°

360°

10

SPINDLE

Speed

Power

Positioning/Repositioning accuracy

Collet

Cooling method

60,000 rpm

1.8kW

0.01/ 0.005 mm

Φ6 mm

Water cooling

OTHERS

All models

North America model

Clamps

CE

FCC

Half-open blank holder(C-CLAMP)/Block holder